Window bends have additional requirements since they’re enclosed. We can perform window bends in sheet metal and polycarbonate parts.

Bend angle limits for window bends

Bend angles up to 90 degrees are allowed for window bends; angles that are 91 degrees and greater will require a custom quote.

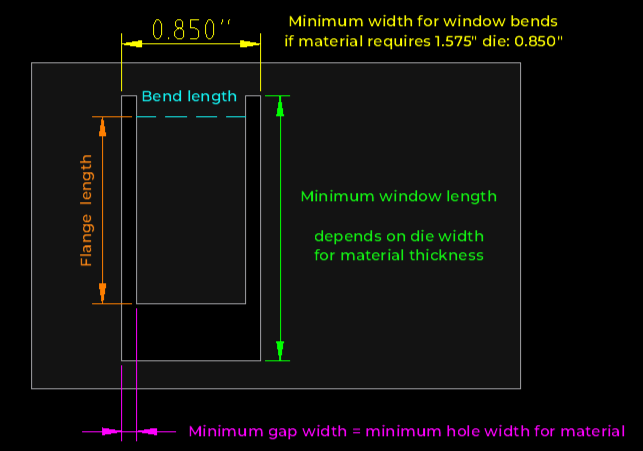

Dimensional requirements for window bends

Ensure your window bend design meets our minimums and requirements for the material you’ve selected!

Minimum cutout width required for window bends

The minimum cutout width for window bends in materials that are bent using a 0.984″ die width or less is 0.450″.

The minimum cutout width for window bends in materials that are bent using a 1.575″ die width is 0.850″. Our thickest bendable materials are typically formed using the 1.575″ die width, but be sure to verify the material specifications to confirm.

Learn how to find the die width specifications for all materials we bend!

Bend length limits for window bends

The bend length limits for window bends are the same as normal bends. You can find the maximum bend length for each material thickness in our processing minimums and maximums page.

Minimum cutout length for window bends

The minimum distance required from the bend line to the edge of the cutout for the window bend will depend on the die width used to bend the material. You can confirm the die width used to bend the material thickness you need in our bending specifications chart.

These minimums assume bends no greater than 90°.

- 0.472” Die Width: minimum 0.55” bend line to cutout edge

- 0.630” Die Width: minimum 0.75” bend line to cutout edge

- 0.984” Die Width: minimum 1.10” bend line to cutout edge

- 1.575” Die Width: minimum 1.50” bend line to cutout edge

Minimum gap width between window “frame” edge and flange

The minimum gap between the edge of the ‘window’ flange and its ‘frame’ will be the minimum hole size value for the material thickness.

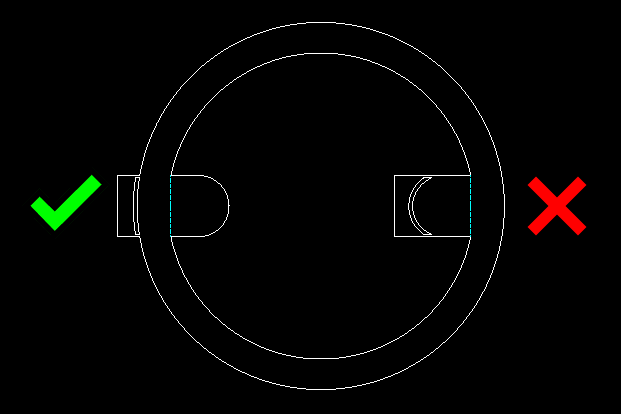

Window bend breakoff tabs for odd flanges

If adding a parallel surface (break-off tab) for a window bend, add it to the exterior of the part.

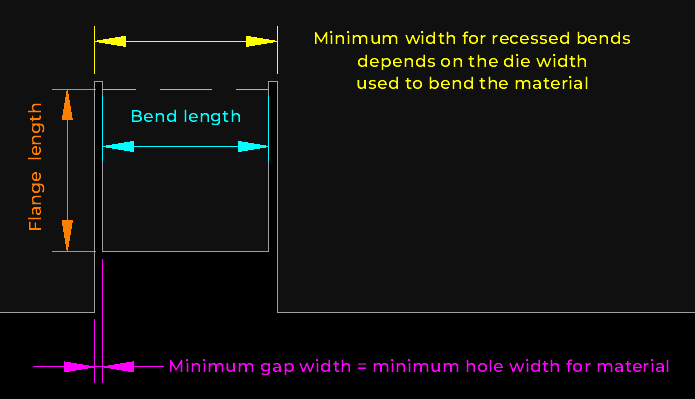

Recessed bend requirements

Recessed bends will have the same minimum width and minimum gap requirements as window bends.

Easy breezy window bending!

Your window bend designs should be successful as long as they meet our minimum specifications and requirements. Review our full bending guidelines before uploading your part file to our website for an instant quote. If you have questions, ask our Support team anytime!