Getting a custom quote with SendCutSend is simple. We offer three ways to place your order: instant pricing, review required, and custom quoting. The best option depends on your part size and processing limits. Read on to find out which method fits your project.

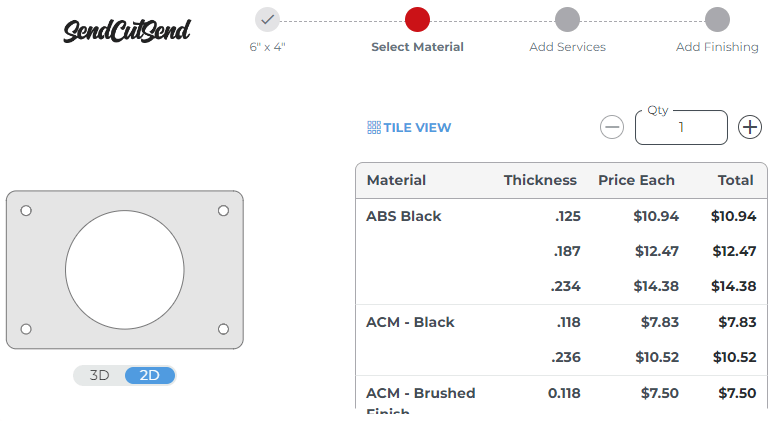

1. Get instant pricing on your part

If your design file meets our part size criteria, you can get instant pricing through our website.

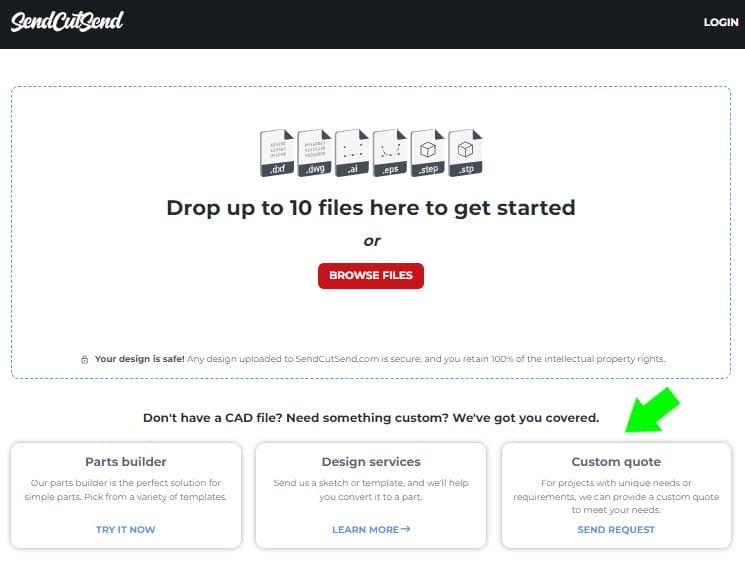

To get started:

- Navigate to our instant pricing system.

- Upload your design in a file format we accept.

- Accepted 2D vector file formats: DXF, DWG, EPS, or AI (Adobe Illustrator)

- Accepted 3D file formats: STEP or STP

- Our system instantly calculates a price for your part after you select a material and add desired services.

You can also create parts in our Online Parts Builder.

Once your parts have all desired services, add them to your shopping cart and check out. Create a free SendCutSend account for step-by-step tracking, 1-click reordering, and more!

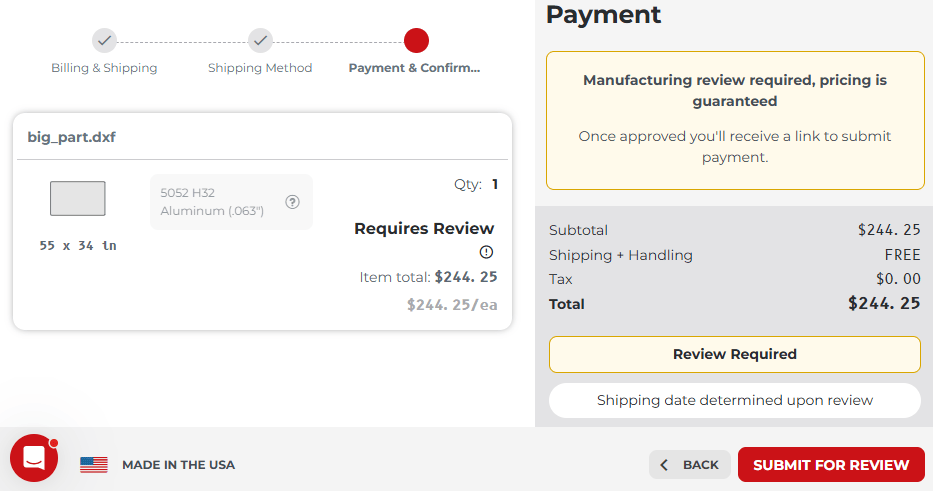

2. Submit your parts for review

If you upload part files to our website and they’re larger than our maximum sizes for instant pricing, you’ll see that your cart requires review.

You can add as many parts as desired to your cart before submitting for review!

After you submit your cart for review, our applications team will review your parts and let you know if we can manufacture the parts as they are drawn. Oversized parts may require a shipping fee, but our team will communicate that to you.

If your parts can be produced, our team will send you a link to pay for the parts.

After placing an order, you can start the reorder process with one click. However the parts will need to be reviewed by our applications team each time you reorder.

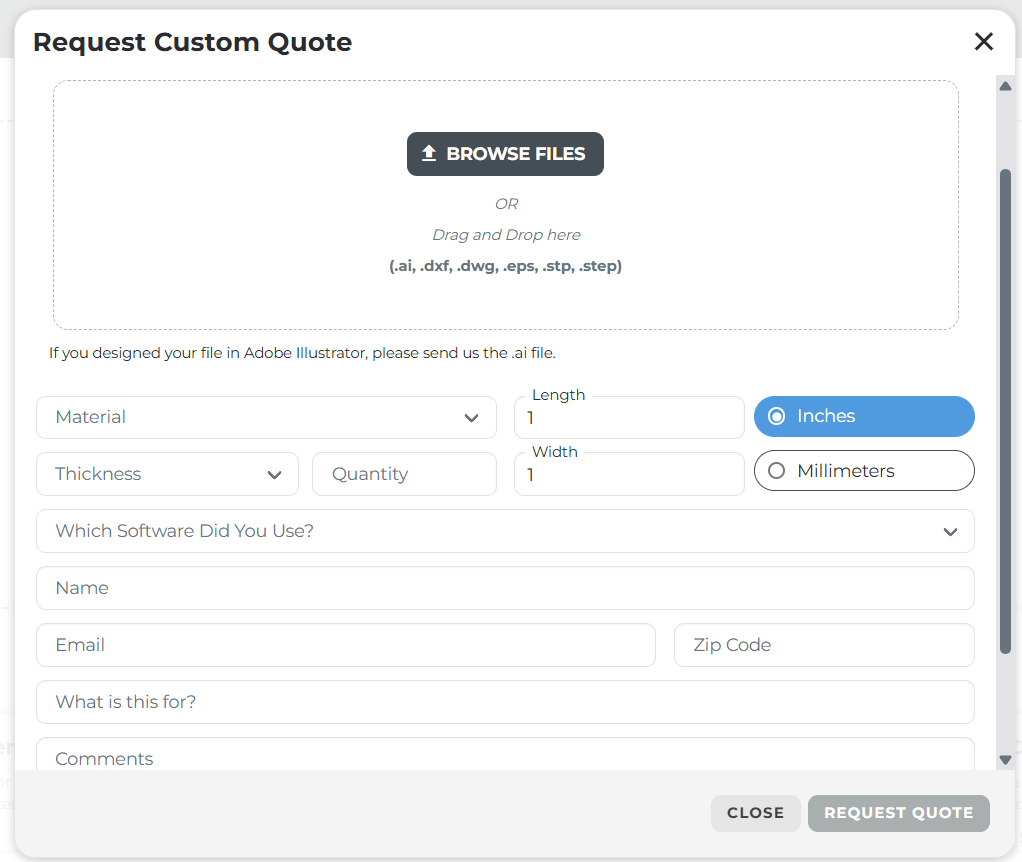

3. Request a custom quote for your part

With our custom quote form, you can upload a part file and confirm details, including material thickness desired and the CAD software used to create the file.

The custom quote process is ideal for requests like

- combined tumbling + finishing services (for example, tumbling + anodizing)

- nickel plating (requires custom quote, $200 USD batch minimum)

The custom quote process is not intended for

- requesting exceptions to our service guidelines (we cannot make exceptions)

- sending file formats we cannot accept for pricing

- take a look at our export guidance to get files we accept from popular CAD programs

- if you only have a PDF, sketch, or template, check out Design Services

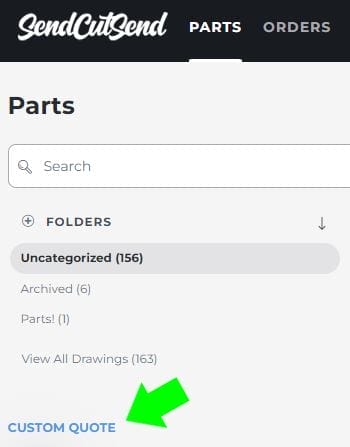

How to request a custom quote from SendCutSend

While logged into your SendCutSend account, you can start a request by clicking Custom Quote in the Parts tab.

You can also start a Custom Quote from the main pricing page.

After you submit your request, our support team will review your file. If your design meets our guidelines, they’ll send you a link you can follow to add the parts to your cart and check out from there. If your part is eligible for instant pricing, we’ll recommend that you upload your file to our instant pricing system instead.

If your file does not meet our guidelines, our team will respond and advise how to update your design so that we can produce it.

Benefits of SendCutSend’s instant pricing tool

- Instant pricing is the fastest way to get your parts into production.

- Instant priced parts can be reordered with one click if you set up a free SendCutSend account.

- Review required and custom quoted parts must be reviewed by the support team each time you need to place an order.

- You can only submit one design file per custom quote request.

Helpful guides for setting up your file

- Material Minimum & Maximum Part Sizes for Cutting

- Material Minimum & Maximum Part Sizes for Processing

- Design Guidelines

- File Setup Checklist

- Troubleshooting Pricing Issues

- Troubleshooting File Upload Issues

It’s easy to get pricing with SendCutSend

To review our pricing options:

- Instant pricing is available for parts that meet our size requirements.

- We have a review process for larger parts so our design-for-manufacturing team can confirm producibility before you order.

- Custom quote requests are best for projects with finishing services that can’t be instantly priced (combined finishing services or nickel plating).

Learn more about getting started with SendCutSend! If you have more questions about how to get a custom quote, contact our Support team.