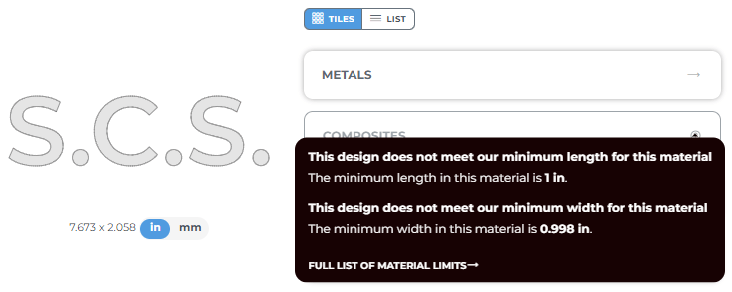

Uploaded your design file to our website and can’t select a material? This is typically because the overall flat part size is too large or too small for the material. Read on to learn how to address material selection issues. If your overall part dimensions don’t look right after uploading your part our tips here can help with that, too!

1. Update your design to meet our size requirements

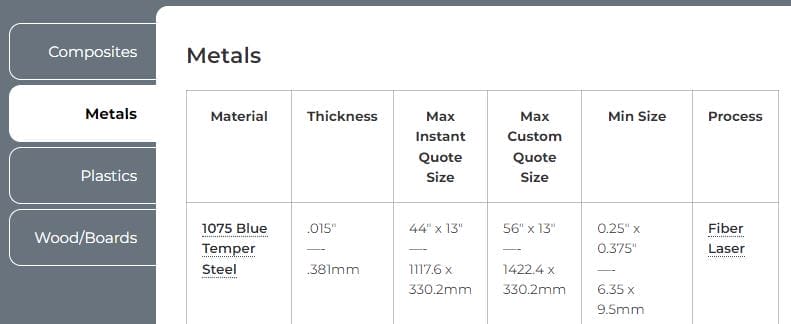

In order to produce high quality parts consistently, we have minimum and maximum part size requirements. The size ranges we offer by material and thickness can be found here:

- Material Minimum and Maximum Part Sizes for Cutting

- shows size ranges and cut method by material

- Material Minimum and Maximum Part Sizes for Processing

- shows size ranges we can produce in eligible materials for all of our post processing services

If your project requires larger parts, you can request a custom quote!

2. For pre-nested files, remove any small parts that do not meet our size requirements

Does your file include parts that are too small for us to cut (such as the dot on a lowercase letter i) ?

If so, remove remove pieces that are too small to cut in the material you need. Then upload your revised file. You should then be able to select the desired material.

We have guidelines for uploading pre-nested files available: Nesting Guidelines

Tip: sometimes files have stray lines or entities due to a bad export. Stray entities can be detected as tiny ‘parts’ and prevent you from being able to select a material. Double check your file to ensure it is free of entities and try exporting your file again. See our CAD export tutorials for help if needed.

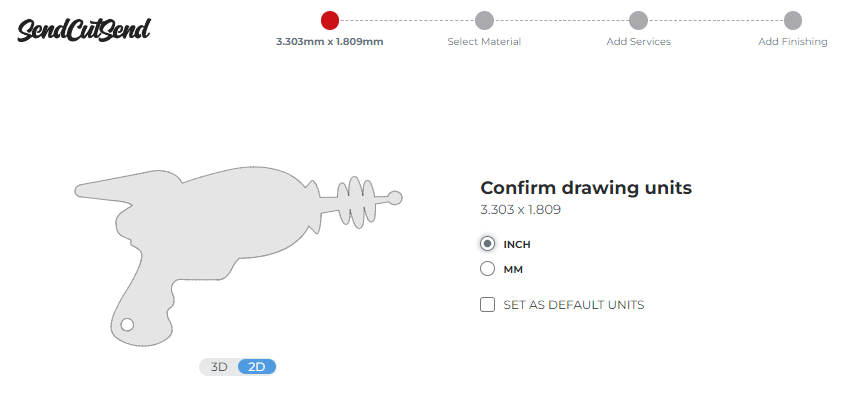

3. The units of measurement in your design file are not inches or millimeters

We require either inch or millimeter units, so if your file is saved in centimeters or meters the sizing recognized by our system will be inaccurate.

4. The design is not saved at 1:1 scale

Please send us your design at the exact size you want it cut.

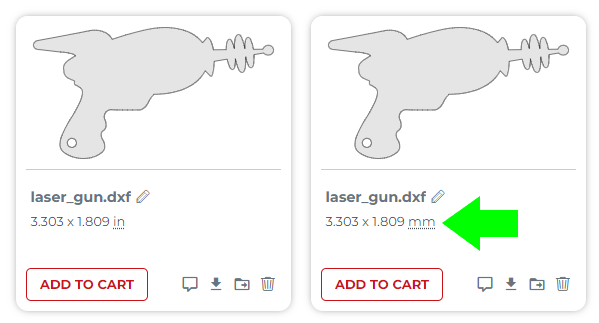

5. The units set for your part do not match the units in your design file

If the units do not match, our system will register your overall part size incorrectly and notify the part is too small for us to cut. You can easily update the units for your part from the Parts tab while logged into your account. Click the units indicated for your part to switch from mm to inches or vice versa.

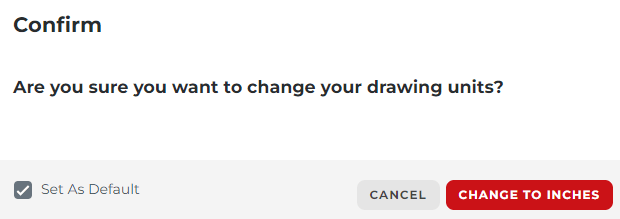

You can set your preferred unit of measurement (inches or millimeters) on our website in your account by ticking the Set As Default box when you change units for a DXF, DWG, EPS, or AI (Adobe Illustrator) file to your account. Please note that it won’t be possible to change units for STEP/STP files in your account.

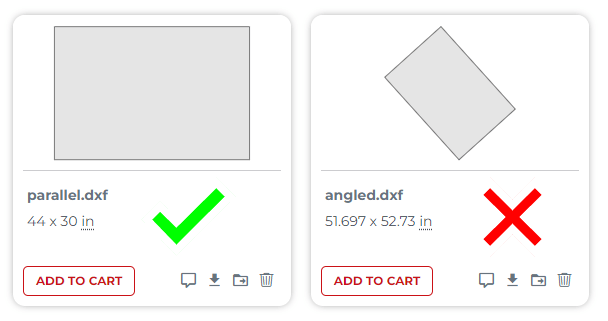

6. Your part is not oriented parallel to the X axis in your file

Your part’s overall dimensions will be interpreted most accurately if you orient the part parallel to the X axis in your design file.

7. We don’t yet carry the material

Is there is a material or sheet thickness you’d love to order but you don’t see it listed? Please request it through our Material Suggestion Form! Please note; we’ll do our best to add your suggestion to our catalog, but submitting to the form does not guarantee we can add the material to our stock.

If you still cannot select the material you need after troubleshooting, revising, and re-uploading your file, please feel free to contact our Support team. Just let us know which design program you’re using, the overall dimensions of the part at 1:1 scale, and attach the file to your message. We’ll be happy to check it out!