Designing a slip fit for mating parts, tab-and-slot joinery, or pin fits in your next project? Keep these best practices in mind!

Cut tolerance considerations

Depending on the cut method for your material of choice, adjust areas that need to fit together to account for cut tolerance. At SendCutSend, our cut tolerances represent the total possible variation from the dimensions of your part as designed.

The cutting process and cut tolerance for each material available here: SendCutSend Materials

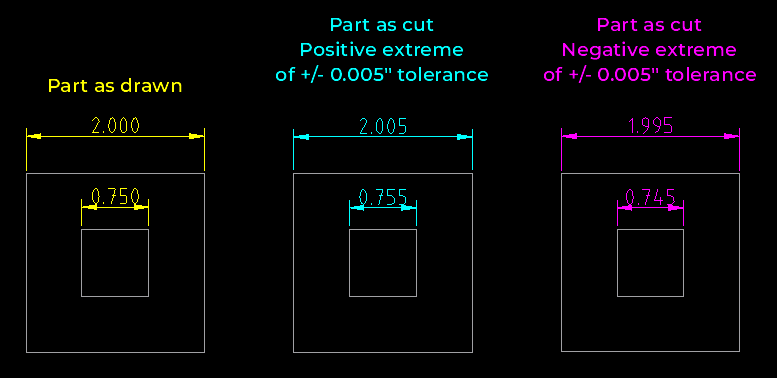

Here is an example of possible outcomes for a part cut from a material with a cut tolerance of +/- 0.005”:

Thickness tolerance considerations

Find the thickness tolerances for each material under the Material Details on each material page. This represents the possible deviation from the advertised thickness. This may be more or less of a concern depending on your application and how your parts will fit together.

Applying tolerance considerations

For specific, in-depth advice on designing tabs and slots to create a slip fit, check out our Designing Sheet Metal Parts with Tab and Slots guide.

In a nutshell, a slot’s size is impacted by the tab’s material thickness and cut tolerances. For joints that need to consider this, you can use the following rule of thumb:

Slot width

Tab width + the tab material’s cut tolerance x 2

Slot height

Tab material’s thickness + tab material’s positive thickness tolerance

+ slot material’s cut tolerance x 2.

5052 Aluminum Material Details

Always check the material specifications to verify the cut and thickness tolerances for the stock thickness you need when designing slot-and-tab parts.

Circular holes & pin fits

If you need pins or bolts to fit into circular holes in your parts, we recommend under sizing those holes by referencing the negative cut tolerance for the material of your choice. This is especially relevant if a close fit is critical for your application or you plan to press fit hardware into holes. When your parts arrive, if the pins or hardware do not fit into the holes you can ream them out if necessary.

If your project requires threaded hardware, check out our Drill Reference Chart for recommended clearance hole size depending on the fit needed.

Tolerance is key

When designing a slip fit for mating parts, there are a lot of variables at play. When you receive your parts there is always the possibility that you’ll need to file a slot or tab down to get the fit you need, or that it could be a bit loose. Given the impact that cut and thickness tolerances and potential warping can have, a Lego-like joint is not to be expected right out of the box.

Please note: the dimensions discussed here lean towards loose-but-safe fitment. It’s possible to create a tighter fit, but please consider the potential for manual adjustment of the part before ordering.

If you’d like assistance adjusting your design, please feel free to contact our applications specialists. Attach your design files and let us know which materials and thicknesses you want to use. We’ll be happy to take a look!

For more design considerations and tips, check out our guides here: SendCutSend Slot + Tab and Tolerances Articles