Can’t add a service like bending/forming, countersinking, tapping, hardware insertion, deburring, anodizing, plating, or powder coating to your part after uploading your file to our website and selecting a material? There are a number of reasons why this might be the case!

General service considerations

The overall flat part size is too large or too small

Each service we offer has minimum and maximum overall flat part sizes for processing. Take a look at our service size guidelines to confirm these limits by material and stock thickness: Processing Minimum and Maximum Sizes

The service is not available in the material and thickness you have selected

Each post processing service is available in specific material thicknesses. You can confirm if a service is available for a material thickness by navigating to the material info page at our Materials Catalog, or referencing the Processing Minimum and Maximum Sizes page.

Bending & forming considerations

There are no bend location lines in your 2D file

If you upload a 2D format file (DXF, DWG, EPS, or AI), ensure there are bend lines indicating the desired location for the center of each bend. We have more information in our bending design guidelines. If your design does include bend lines but they aren’t showing up, then check out these troubleshooting tips.

Bends are not modeled in your 3D file

If you upload a 3D format file (STEP or STP), ensure it meets our 3D file guidelines. You’ll want to model the formed flanges in your design. Our quoting system should recognize the definitions of the flanges in your file, but confirm they’re correct before checkout.

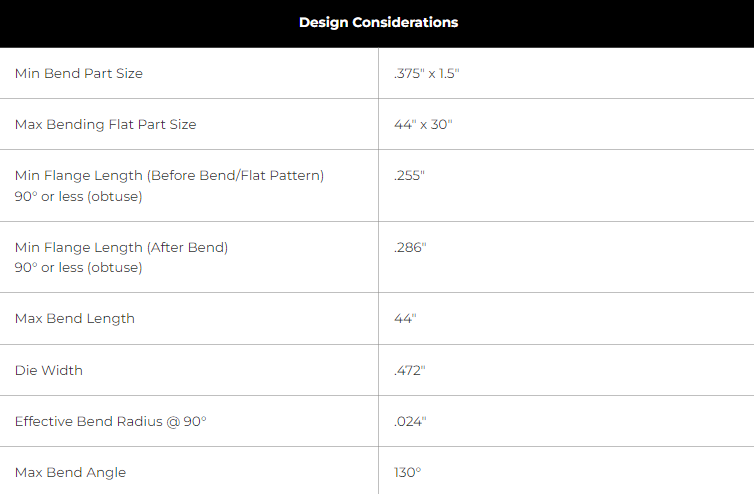

The desired bend angle is too acute for the material thickness selected

The maximum bend angle possible for bendable materials varies based on material thickness. You can confirm the maximum bend angle for a material thickness by navigating to our Material Catalog, finding the desired material info page, and scrolling down to the Material details and specifications. All critical design specifications including maximum bend angle are listed there.

Learn more about finding material specifications.

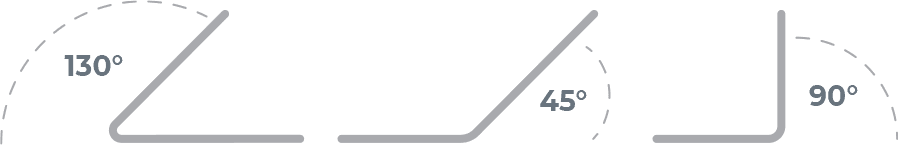

Please note, we call out angles from the outside of the bend. Think of it as the number of degrees the flange bends from a flat position.

Hole operation considerations

Holes are over 4.00″ wide

Tapping, countersinking, dimple forming, and hardware installation services cannot be applied to holes over 4.00″ wide. We automatically resize holes to perfectly fit the operation you choose and the maximum for this is 4.00″.

Holes are not circular

Holes must be circular to have hole operations applied to them. Ensure holes in your design are not oblong if you’d like to add tapping, countersinking, or hardware installation to them.

Holes have many anchor points or nodes

Sometimes design software will export files with dense nodes or anchor points in curved areas. If holes are circular but are made up of many small line segments instead of arcs, our system may not detect them as circular holes. Take a look at our tips on exporting files with fewer nodes!

Holes are too close to cut edges or bend areas

All hole operations require a minimum amount of space between holes and other cut features or bend areas. If the holes you want to select for processing are too close to other features, our pricing and configuration system typically blocks ineligible tap, countersink, dimple, or hardware sizes.

Be sure to review our service guidelines and material specifications to ensure your design provides adequate space for all needed hole operations. For PEM hardware insertion, you’ll want to check the distance specification for the hardware SKU you need in our Hardware Catalog.

Finishing considerations

There is not a hole at least 0.063″ wide

Finishing services (anodizing, plating, and powder coating) require a hole at least 0.063″ wide for processing.

All things considered!

If these tips do not resolve the issue, try reviewing our Design Guidelines and this guide: Why can’t I get a quote?

Please feel free to contact our Support team for assistance and attach your design file. Let us know what services you’re trying to add and we’ll be happy to help!