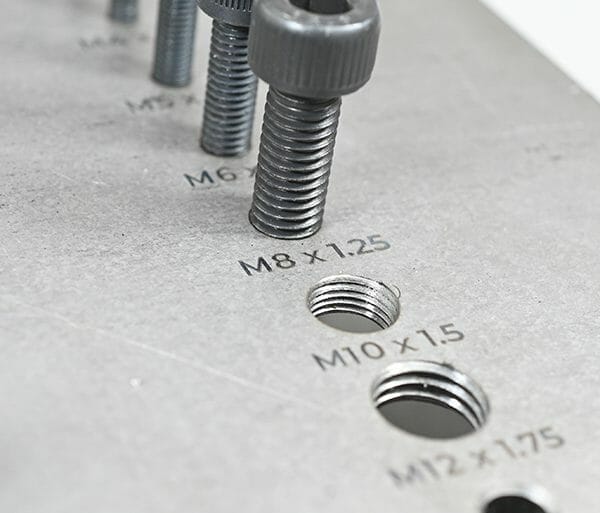

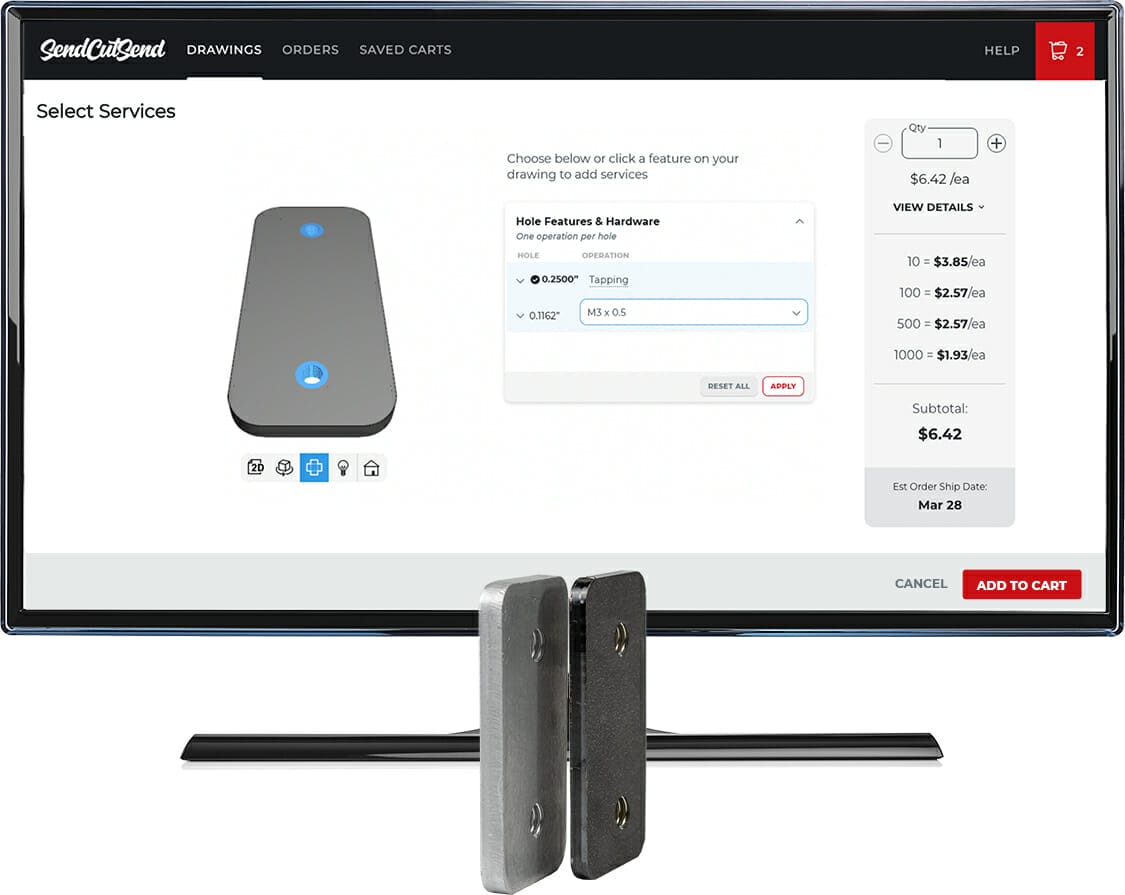

What is the ideal hole size and thread engagement for tapping?

Designing the correct hole size when preparing for tapping is important. Holes that are too large may cause the tap to strip out or fail. If the hole is too small, it will cause the tap to bind, create excessive heat, wear, and could result in a broken tap trying to cut too much