Traditional fabricators need technical or mechanical drawings with callouts to produce parts and apply services. At SendCutSend we do things differently. Why? We believe makers of any skill level or educational background should be able to make cool stuff with us.

Simplicity through transparency

We cut your parts exactly as they are designed in your 3D file (STEP or STP format) or 2D vector file (DXF, DWG, EPS, or AI format) within our tolerances. We provide detailed information in our guidelines and FAQs explaining why your final, finished part might deviate from the design on paper.

- Tolerances & Standards FAQs – common questions about cut tolerance, material tolerance, bending tolerance, and kerf compensation.

- CNC Machining and Waterjet Cutting service guidelines – since the cut paths for these processes are substantially wider than a laser beam, our guidelines explain what to expect in routed or waterjet cut materials.

- Bending Specifications – the effective internal bend radius and K factor for each material and thickness is fixed and cannot be changed upon request.

- Tapping, Countersinking, Dimple Forming, and Hardware Installation design guidelines – when you add hole operation services to your part, we automatically resize the hole selected to match the tap, countersink, dimple, or hardware size you choose. See the thread/tap hole size chart, countersink size charts, dimple size chart, or hardware catalog to confirm the hole size for each operation size.

- Material Catalog – find material details, properties, and design specifications for each material thickness on the material info pages.

With intuitive part configuration, you don’t need callouts

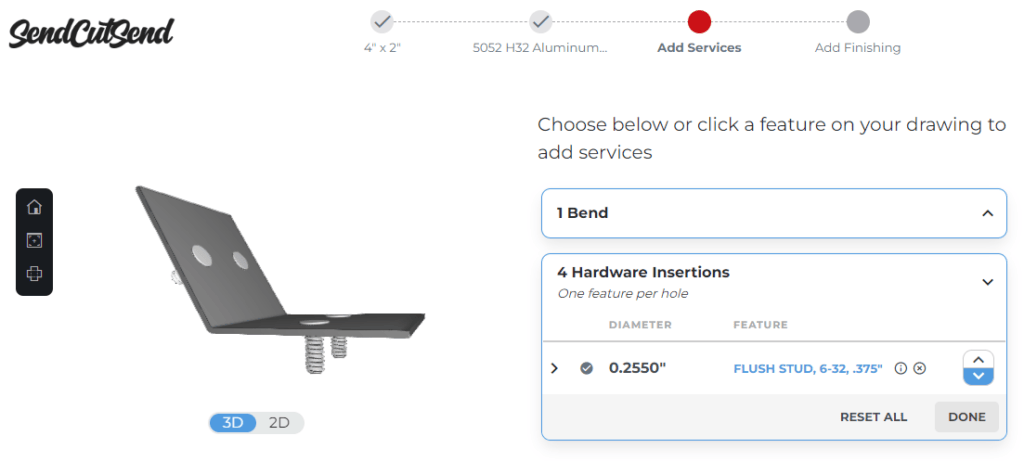

Upload your part file, choose a material, and start adding eligible services. See our step-by-step instructions for ordering parts if needed!

When you place your order, we’ll be able to see the definitions you specified for each part and service. This allows us to produce your parts accordingly – no callouts required.

Please note: if you need specific tolerances for specific dimensions in your design, we won’t be able to accommodate them. For example, we’re not able to provide a tighter cut tolerance for one cut edge versus another. Learn more about our cut tolerances.

The future is now!

Upload your design file and take our in-app preflight tools for a spin. No technical or mechanical drawings needed! If you have specific questions reach out to our Support team anytime.