Mirrored parts are easy to order at SendCutSend. Learn about operation and material considerations for part mirroring and how to order these types of parts here.

Ordering parts with opposite operations

If you need to order a set of identical parts but half of them need operations like bending, countersinking, dimple forming, or hardware installation performed in the opposite direction, we’ve made it easy!

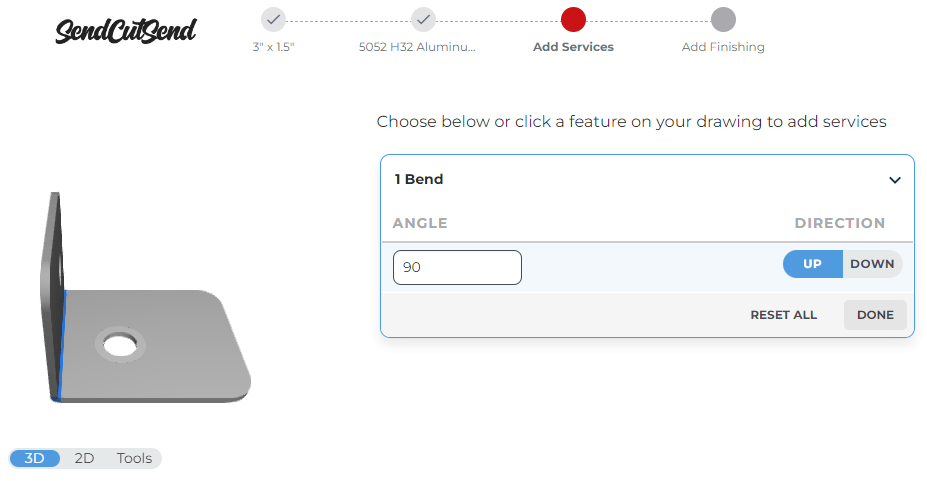

First, go through the instant quote and service configuration process as you normally would with half the total part quantity that you need.

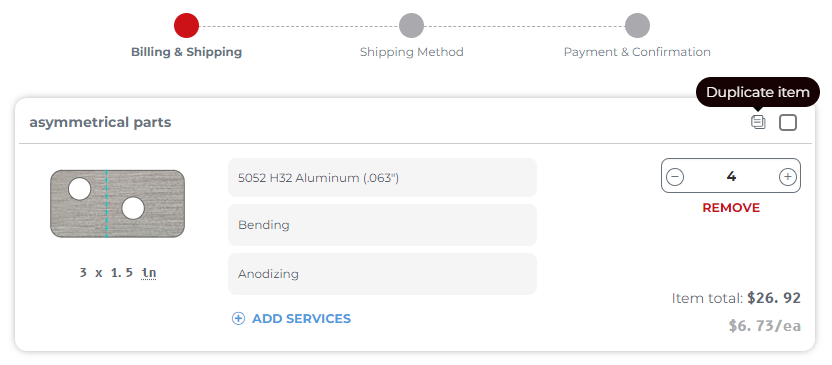

After adding the parts to your cart, hover over the line item and then click the Duplicate item button that appears.

Clicking the Duplicate item button will automatically initiate the part configuration steps.

Update the operations to the opposite direction, save, and then add the parts to your shopping cart. That’s it!

Ordering parts with mirrored orientations

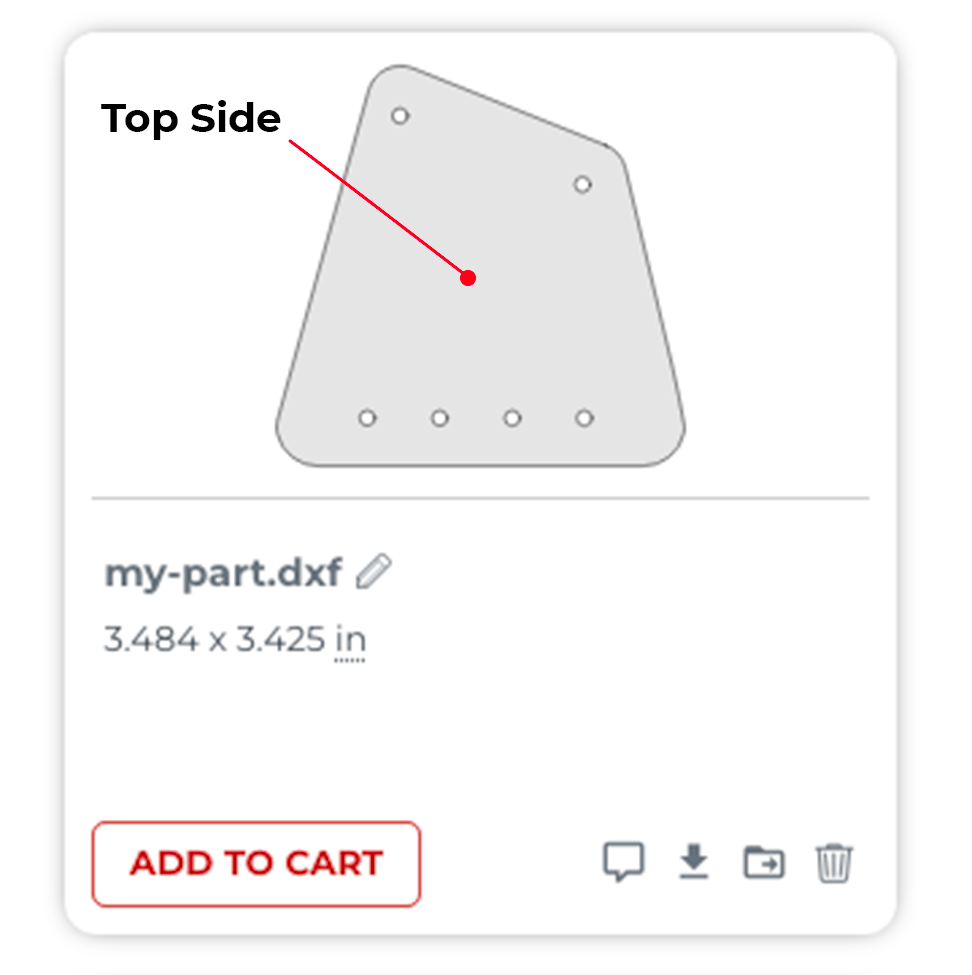

Does your project require materials that have distinct top and bottom sides like ABS, ACM, mirrored acrylic, or hardboard? Consider whether the orientation of the top side is important.

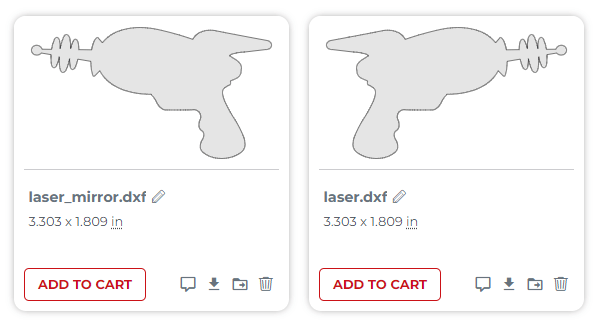

If you need parts in these materials “mirrored”, save a flipped version of your design and upload the file as a separate part. This will ensure the parts are cut with your desired orientation.

Mirror mirror!

The Duplicate item button is a helpful time saver for parts with opposite operations. If you need mirrored parts in materials with distinct top and bottom sides, it’s necessary to upload separate files to ensure that the top side is correct for your project. If you have any questions about part setup reach out to our Support team!