If you’re looking for our material bending specifications, sheet metal rules, or gauge tables, you’ve come to the right place! We provide specifications for K factor, bend radius, and more for all materials we bend.

Keep in mind, our material bending specifications are set by stock thickness and cannot be changed. Be sure to set your design up using our specs to ensure your parts turn out as designed, within our bending tolerances.

SendCutSend material bending specifications

Our material bending specifications include:

– minimum and maximum overall flat part sizes before bending

– maximum bend length

– minimum flange length

– maximum bend angle

– bend angle tolerance

– die width used to bend the material

– bend radius

– K factor

– bend deduction

– minimum bend relief depth

– joggle bend minimum bend line to bend line distances

– joggle bend maximum flange length

There are additional limits for bending that apply to all materials we bend. Learn about them in our Bending Guidelines!

Where to find SendCutSend material bending specifications

You can find our material bending specifications within a few resources we provide.

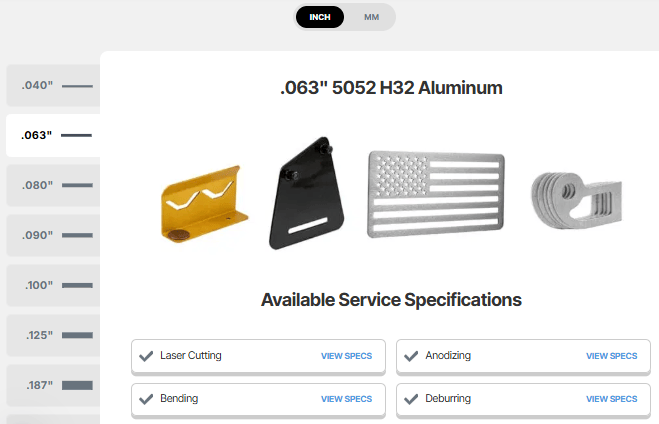

1. SendCutSend Material Catalog

Bending specifications for each material thickness we stock can be found in our Material Catalog.

To find bending specifications in our Catalog,

1. Filter materials in the Catalog by Available Services and select Bending. Then navigate to the page for the material you need.

2. Once on the needed material page, you’ll see several quick links at the top of the page. Click Specifications to jump to all material specifications and details.

3. In the material specifications and details area, select a material thickness. You can use the inch/mm toggle at the top to change the specification units.

4. Click View Specs for Bending.

You’ll then see all bending specifications for that material thickness, including K factor and effective bend radius!

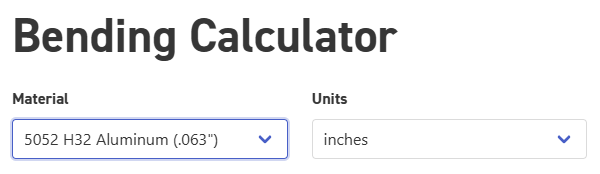

2. Bending Calculator

Our Bending Calculator allows you to enter the desired overall outside base and flange lengths of a part you’re designing for bending services and find the flat pattern dimensions required to achieve the finished dimensions.

You can also use our Bending Calculator page to simply look up bending specifications!

Option 1: choose your desired material thickness from the drop down menu, update the bend angle if desired, and then then scroll down to the Advanced Details.

Please note: changing the bend angle will update the Bend Allowance and Bend Deduction values in the Advanced Details. However, the bend radius and K-factor values will remain the same. Our bend radius specification is based on a 90 degree angle. Learn how the math works in our detailed tutorial!

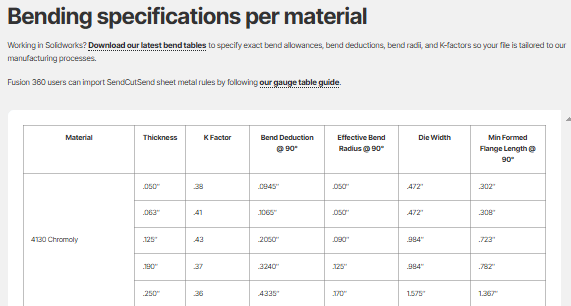

Option 2: keep scrolling down to our handy bending specifications table. Here, you can reference all key bending specs for our bendable materials at once!

3. Free gauge tables and sheet metal rules for SolidWorks and Autodesk Fusion

SolidWorks and Autodesk Fusion are some of the most popular CAD modeling software today. Since so many designers and engineers use these tools, we’ve made it easy to import our material bending specifications and ensure your parts turn out as expected!

How to Import SendCutSend’s Latest Autodesk Fusion Sheet Metal Rules

How to Import SendCutSend’s Latest SolidWorks Sheet Metal Gauge Tables

Please note: when used as directed, our gauge tables and sheet metal rules will automatically apply the correct bend radius, K factor, and bend relief specifications to designs, but they will not enforce minimum flange length or overall flat part size requirements. Check all material bending specifications for your chosen material thickness in our Catalog to ensure your part meets all guidelines!

Great expectations!

Remember: it’s critical that bent parts are set up using our bend radius and K factor specifications for the material thickness you plan to use; this ensures your parts will have the final formed dimensions desired, within our bending tolerances.

When designing in a 2D software like AutoCAD or QCAD, use our Bending Calculator to find the flat pattern dimensions required to receive the formed part you need.

When designing in a 3D modeling software like Autodesk Fusion or SolidWorks, set up your sheet metal rules or gauge tables using our bending specifications.

Our material bending specifications can be found in our Material Catalog or Bending Calculator. If you have any questions our US-based Support team is available to help!