Having trouble uploading a STEP or STP format file to SendCutSend’s website? There are a few reasons why that might be happening! You’ll want to ensure that your design meets our 3D file guidelines.

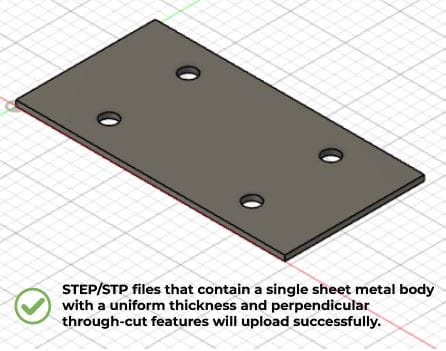

For a STEP or STP file upload to be successful, it must meet these criteria:

Single, solid sheet metal body (no assemblies or mesh bodies)

- we need your STEP/STP file to contain a single, solid sheet metal body

- we cannot accept files with multiple bodies stitched together / assemblies

- we cannot accept files including mesh bodies

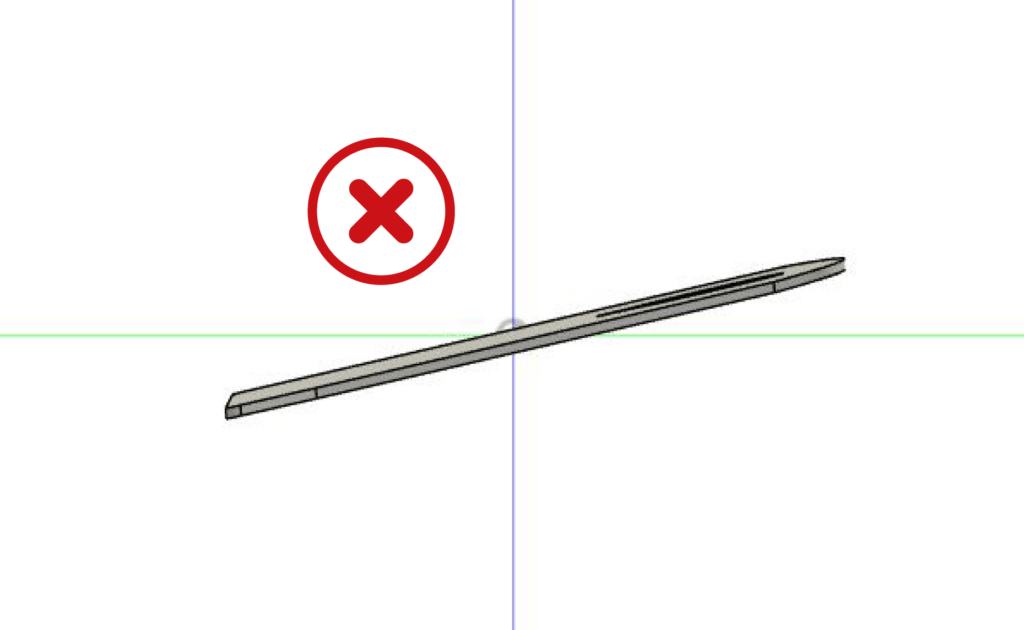

Part aligned flat to drawing plane

- we need the part in your STEP/STP file to be aligned flat to at least one drawing plane

- we cannot accept files with parts that are not aligned flat to any plane

Part without dimensional features

- we need your STEP/STP file to contain a part without dimensional features

- we cannot accept a body with a non-uniform thickness

- we only provide 2D through-cutting in flat sheet materials at this time

- fillets, chamfers, countersinks, counterbores, or other 3D features will prevent uploading

- please see our design guidelines for countersinking, hardware insertion, and tapping services if needed

- we require simple through-holes in your uploaded file; after you have selected a material, you can add and configure services before checkout

Sheet metal body using correct material thickness

- the part in your STEP/STP file must be a “sheet metal” body – not an extruded flat pattern

- please set up your design with a thickness offered in SendCutSend’s material catalog

- parts designed with a thickness greater than 0.500″ may not upload successfully

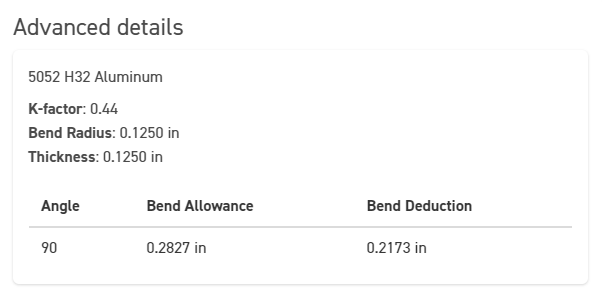

Sheet metal body using SendCutSend specifications for bending

- designs with bending/forming services must have SendCutSend’s specifications applied

- set up a sheet metal rule with SendCutSend’s K factor and bend radius for the material

- this ensures that your part will be bent accurately; you can find the bending specifications for the material and thickness needed for your part here: Bending Calculator

- Using Autodesk Fusion or SolidWorks? Download our gauge tables to easily apply the right specs!

Avoid complex designs with many cutouts and detail

- designs with many features should be exported to DXF

- these designs result in large file sizes in the STEP format

- if your part will be detailed, export your design to DXF for successful processing

Revise your file to meet our 3D file requirements and design guidelines, then try uploading again.

If your file still doesn’t upload successfully, please contact our Support team. Let them know which program you’re using to design your part and attach your file so they can take a look!