Etsy is truly a marvel of the 21st century. The artists, crafters, and makers of the world have come together to create a digital ocean of online stores. But as amazing as Etsy is to browse as a shopper, it’s equally as hard for sellers to get noticed among the stiffly competitive crowd.

If you’re an Etsy seller, you’ve undoubtedly put meticulous work into optimizing your SEO to help people find you, but at the end of the day, it’s your product line and efficiency of your order fulfillment that will separate the success of your shop from the ones who get buried in the Etsy abyss.

If you want to beef up your product line, you may be thinking, “I have grand ideas for products, but no means for creating them,” we have a solution that may just be the answer to all of your product-producing dreams.

SendCutSend is bringing small batch laser-cut products to people like you and me. With SendCutSend, a world in which you can create anything you can draw just became a reality.

Visions of possibilities are probably already forming in your head, but here are a few ideas to fuel your inspiration even more.

17 Creative Laser Cutter Project Ideas

We’ve compiled some beautiful examples of laser cut projects here to help inspire ideas for your products. For even more inspiration, check out our examples page and our Instagram.

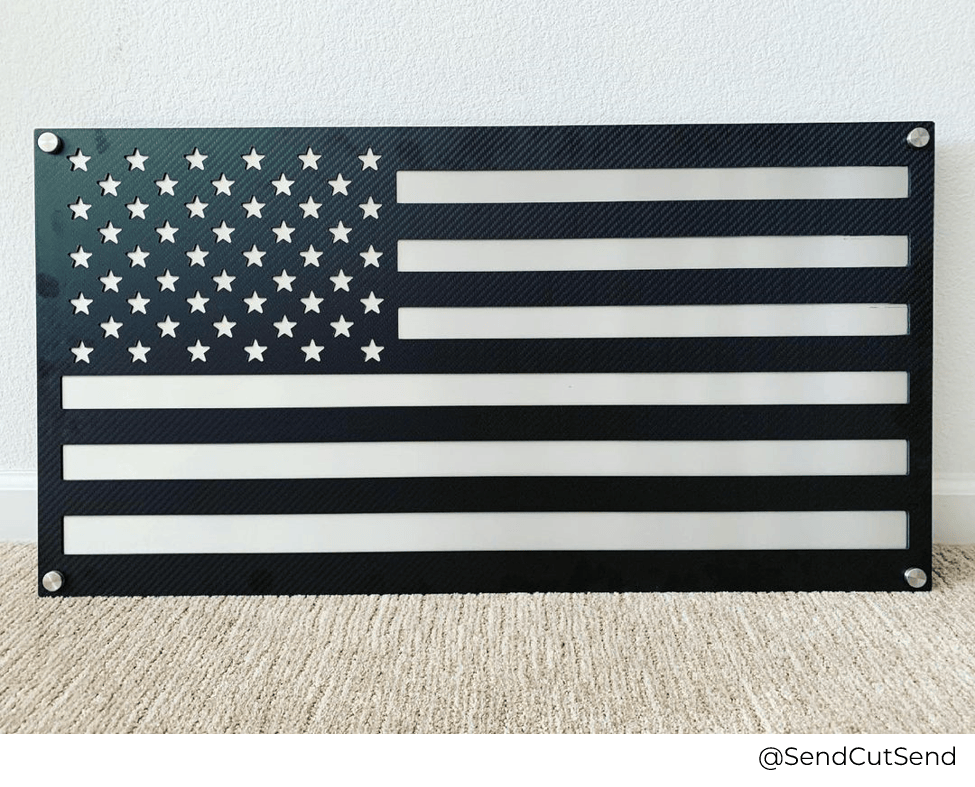

Laser Cut Wall Art

There’s nothing quite like a large metal piece to be the focal point of a room. Design and cut multiple individual parts (like clock gears or simple shapes). Arrange, and weld them together on your own, or simply have one piece cut from solid metal.

Mounting metal on wood can give your metal art an even different look with little extra cost or skill.

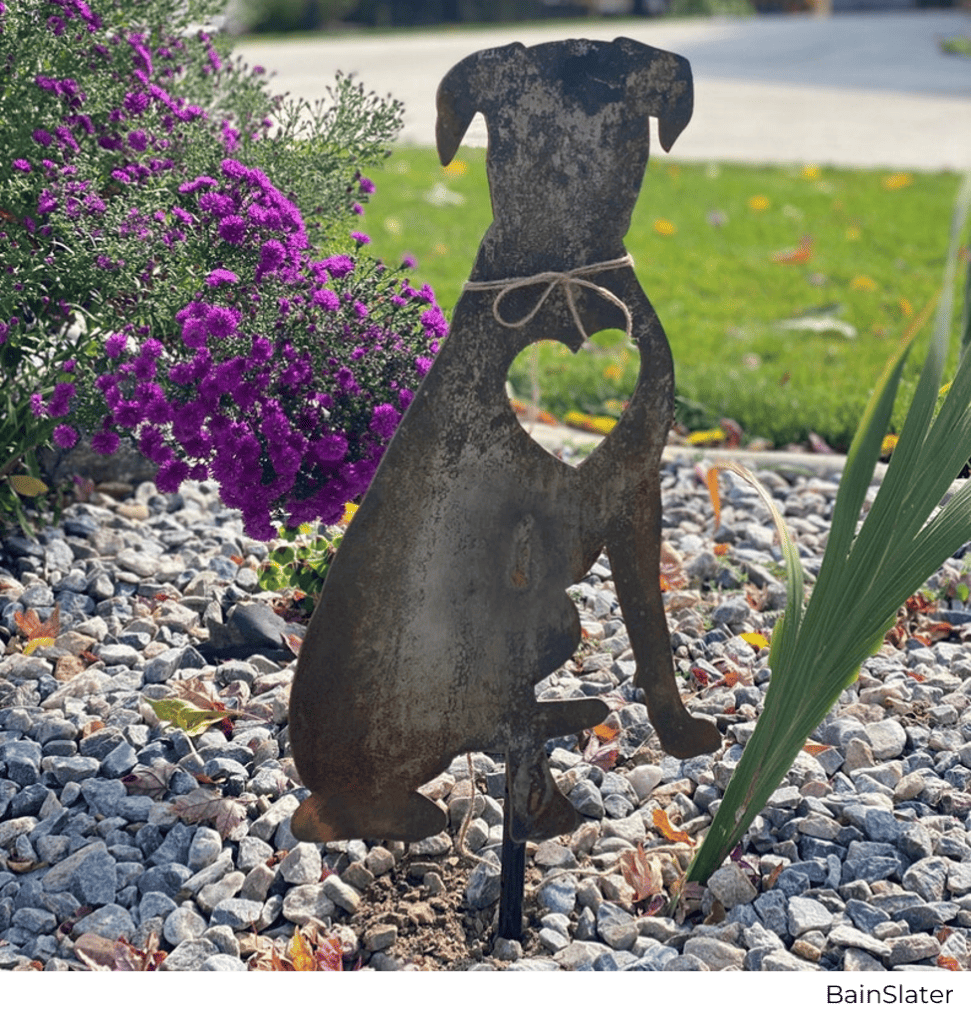

Laser Cut Yard Art

When the weather is nice, basking in the backyard can make the outside feel as much a part of your home as the inside, so why only decorate there? Metal gives you the versatility to cut products that can live outdoors. Think yard signs, mailbox monograms, or even weather vanes.

Laser Cut Coasters

Cut out a popular logo, creative shape or even just a beautiful material to use as a coaster. Add a thin layer of cork to the bottom to keep it from slipping easily and you’ve got yourself a coaster. Coasters are likely to get wet (that’s their job after all) so consider adding a protective finish.

Laser Cut Containers

People have stuff, why not make some custom containers to put that stuff in? Collectible holders are easy to customize with unique shapes and styles. Generic boxes can be made to look like books, or given an industrial look made from metal and rivets. Toy organizers can be great for parents with kids and toy collectors.

How about desk organizers?

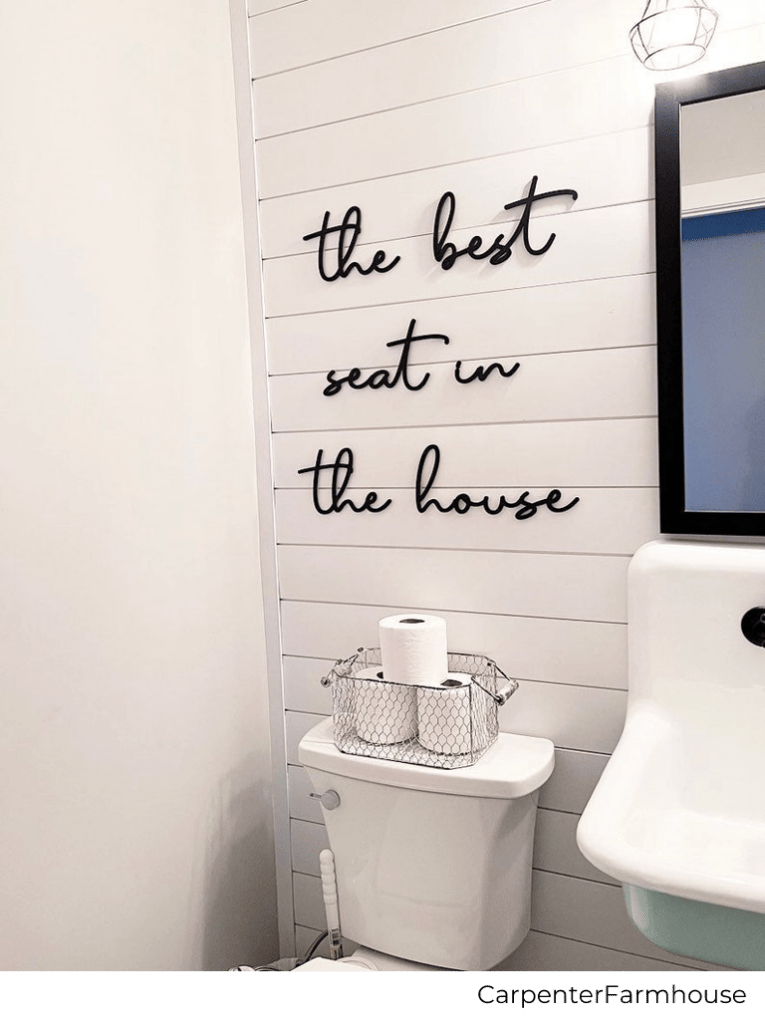

Laser Cut Home Decoration

Homes are full of decorative items. A simple phrase cut out of attractive material can be charming, witty, funny and can even tie into a specific room. Kitchens, garages, game rooms, home offices.

The bathroom is a gold mine for some potty humor products.

Laser Cut Tools

Etsy is full of custom made tools. Sometimes the design is custom, sometimes just a simple bottle opener from a nice material can be a great item to sell.

Laser Cut Templates

You can sell products to help other people make things. Stencils for paint and router templates are a great fit for laser cutting. You can provide lettering templates, cutting board shapes, shapes of countries and states. The list is endless.

Laser Cut Gifts

Etsy sells tons of gift items. Making a standard item like a bottle opener with styling from a popular movie turns it into a great gift for movie fans. Incorporating graphics from different interests like hiking, camping, woodworking, racing and even political slogans can make almost any simple item like a key chain a fun gift.

Laser Cut Signs

This one basically speaks for itself. Signs can be made in so many unique ways that are simple to achieve with laser cutting. Layers of painted plywood, a shadow box style from anodized aluminum or just a clean silhouette from powder coated steel.

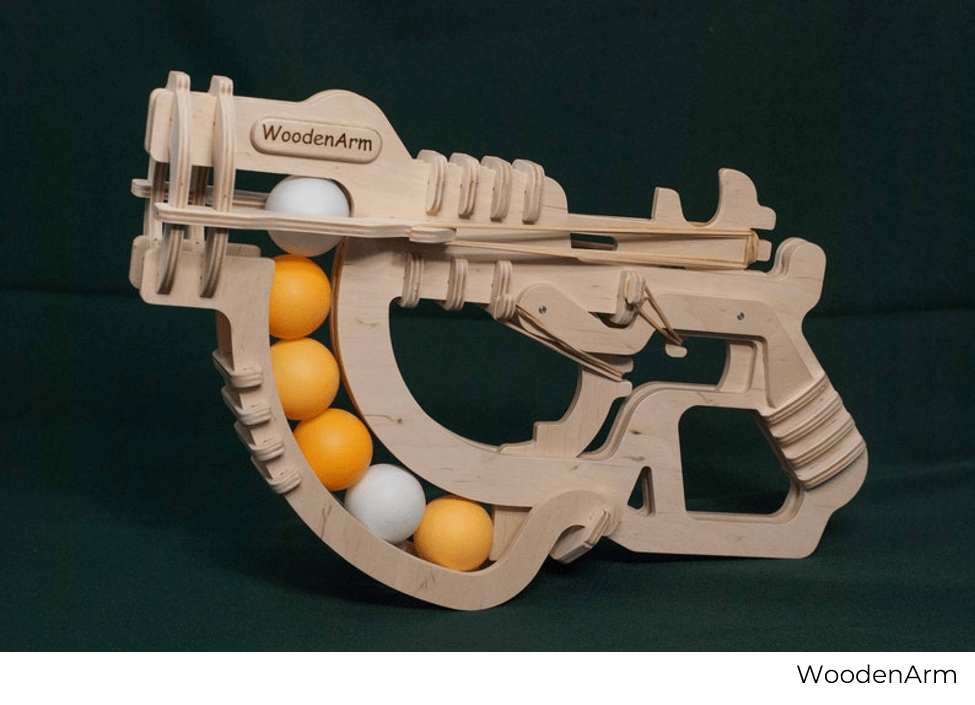

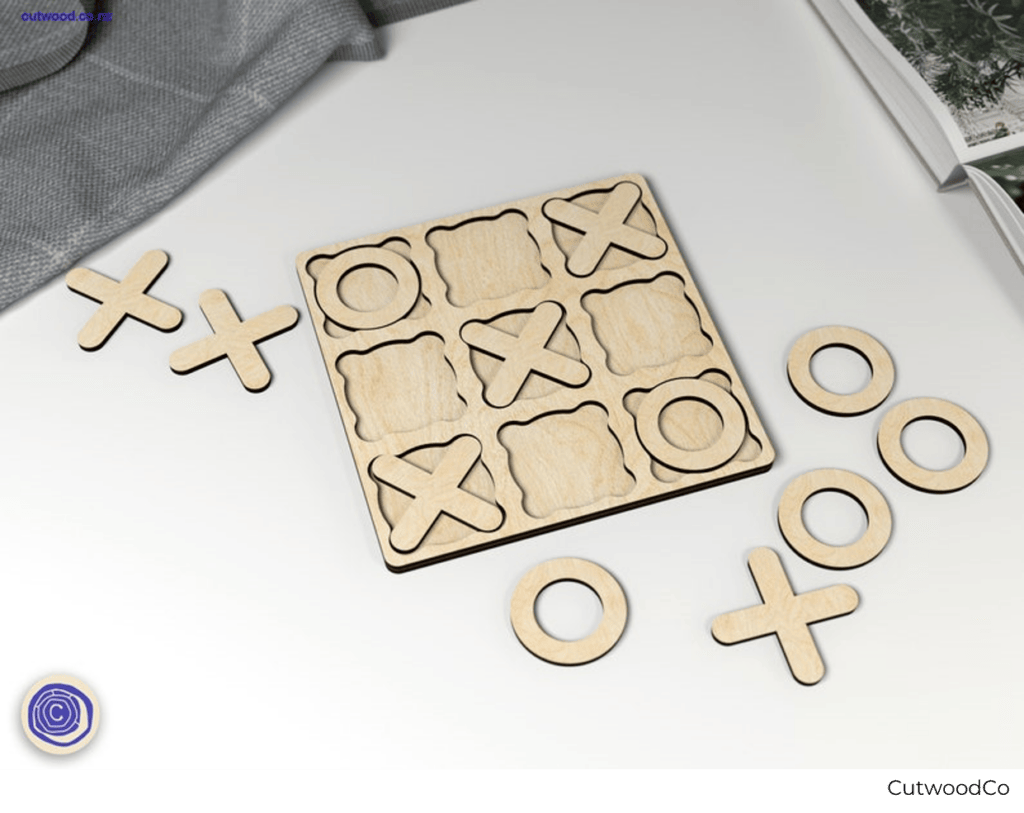

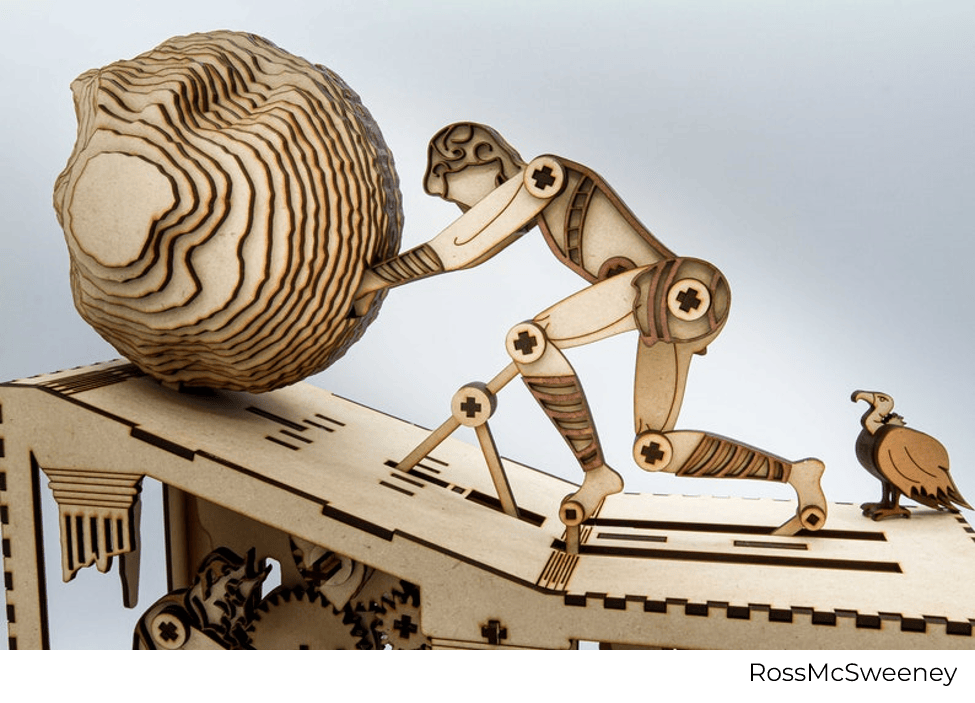

Laser Cut Toys

Whether you sell full toys or kits to assemble your own toys, there’s a big market for custom toys.

They can be complex designs or simple shapes. Puzzles are a fantastic application for laser cutting.

Laser Cut Holiday Decorations

There’s always a new holiday coming up, which means there’s always an excuse for new decorations. Christmas tree ornaments, spooky Halloween decorations, Easter egg holders, 4th of July flags… Sellers can make their entire business successful with nothing but holiday decorations.

Laser Cut Business Cards

Business cards (or any card in general) doesn’t have to be made from paper, they can stand out by being made from metal. Laser cut a company logo, QR code, website or name into a thin piece of stainless, aluminum, copper, brass, titanium even carbon fiber could look amazing.

Laser Cut Trophies and Plaques

Virtually any material can make a beautiful trophy or plaque. Different shapes, designs and materials can make your placards stand out.

Laser Cut Mechanisms

If designing interesting mechanisms is your thing, you should have no problem selling your designs. Whether they’re simple or complex, people that don’t know how to design mechanisms find them fascinating.

Laser Cut Targets

Did you know SendCutSend carries AR500? Not only is it extremely wear resistant, it’s the most common material for making firearm targets. Cut the shape of a squirrel out of AR500 and you’ve got a simple knock down target for hunters and firearm enthusiasts.

Laser Cut Light Fixtures

Adding lighting to any product takes it to the next level. You can add a simple tea light or custom LED lighting controlled by a microcontroller. Playing with shadows is another way to make interesting products.

Laser Cut Furniture

Not everything sold on Etsy fits on a shelf. You can sell the shelves themselves too.

Metal table legs are another popular furniture item a lot of woodworkers buy instead of make.

But I’m Not That Creative

Sometimes you’ve got the desire to sell products online, but maybe don’t enjoy the creative part of designing your own products. Fear not, there are thousands (more!) of sets of plans you can purchase, ready to laser cut from the materials of your choice. Don’t be discouraged if the business side of things is your strength, you can always outsource the rest. Since SendCutSend can do the cutting and finishing for you, the hardest part is deciding what types of products you want to sell.

Laser Cutter Projects Materials

All of them, literally. There’s a useful way to use virtually any material, the key is finding the right pairing of project and material.

Metals

Mild Steel is a low cost, strong metal. It can be plated or powder coated for a finished look and some corrosion protection. If you need some serious strength there’s 4130 Chromoly Steel. For the ultimate in wear resistance there are AR400 and AR500.

Aluminum is a lightweight, attractive material. Anodizing is a great way to boost both the appearance and corrosion resistance of aluminum parts. SendCutSend carries 4 different grades of aluminum, all with their own unique strengths.

Stainless Steel can be polished to a mirror finish and naturally resists rusting. It’s available in multiple grades.

Brass and Copper can give a product an antique or steam punk look. You can get even more interesting looks with a little patina if you want a more rustic or worn look.

Titanium is a unique material great at resisting heat and can give any product a more exotic feel. Multiple grades of titanium are available.

Woods

Baltic Birch Plywood is inexpensive and has a stable consistent construction. It looks great natural or painted and can be joined with wood screws or wood glue or even nails

Chipboard is a very inexpensive material, great for prototyping builds before you make them out of more expensive materials. Because it’s recyclable, it can be a great option for one time use or disposable items like stencils. Don’t underestimate the power of including “ made from 100% recyclable material” in your product description on Etsy.

Hardboard is similar to chipboard, but a little tougher and thicker. A good choice for things like puzzle pieces and signs.

MDF is available in multiple thicknesses. It takes paint extremely well and can leave a super smooth finish. It can be used for everything from small decorations to full size furniture.

Plastics

ABS is popular in 3d printing. It’s relatively strong and low cost.

Acrylic is a super versatile material. Available in a range of colors including clear and smoked. It cuts beautifully and can be used for a ton of different products.

Delrin is used a lot in engineering applications due to its stability, durability (against wear, chemicals, stress, etc.) and it is self lubricating.

HDPE (High Density Polyethylene) and UHMW (Ultra High Molecular Weight Polyethylene) are both versions of polyethylene. Both are tough and inexpensive materials to build from. Great in wet weather or marine applications.

Polycarbonate is similar to clear acrylic, but much tougher. It isn’t quite as scratch resistant as acrylic, but it makes up for it in toughness and strength.

Composites

ACM (Aluminum Composite Material) is available in black, white or brushed aluminum finishes. It’s low cost and lightweight with a unique look.

Carbon Fiber is one of those materials that can give any product a modern look. It’s extremely strong, extremely light and can be used in all sorts of products.

Cork can be used as a seal, to absorb vibrations and prevent scratches. It’s a great option to line the underside of a decorative item so it doesn’t slide as easily and doesn’t scratch the surface it’s sitting on. Adding a cork bottom is one of those little details that show the quality and care you take in your products.

G10/FR-4 is used a lot in the knifemaking world as a handle scale material. It’s also great in wet environments and with electronics.

LE Phenolic is similar to G10 and carbon fiber, but made from linen giving it a unique look. It’s durable and dimensionally stable and lighter than aluminum.

Often a single design can be made from multiple materials allowing you to offer more variety without having to do double the work.

The laser cut material doesn’t even have to be the final sellable product, it can be just one part of the final product. You can also add custom touches to stand out from the crowd, like painted lettering, engraving, or combine multiple materials. See Methods for Joining Laser Cut Parts and Alternatives for Welding.

Laser cut materials don’t need to be part of the sellable product at all, they can be useful for making the product. We mentioned templates and tools above as possible sellable products, but you can laser cut templates, tools and fixtures to help you create your products.

Don’t Forget the Finish!

Raw materials can look great, but to take your products to the next level consider adding a finish like anodizing or powder coating. Not only will these make your products look amazing and high quality, they can help your products be more durable. Selling quality, long lasting products is a great way to bring back repeat customers, get great reviews and help spread the word about you as a seller.

Tips for Designing Laser-Cut Products

If you’re ready to start designing laser cut products, there are a few best practices to adhere to:

Design in a Vector format: Illustrator, AutoCAD, Autodesk Fusion are just a few platforms that create files in vector. But if you don’t know or have one of these apps, all is not lost. Inkscape is a free, simple to use design platform. Or, if you’ve already created your file in Photoshop, or somewhere else, we have tutorials on how to convert your raster file to vector.

One of the big benefits of vector formats (besides being helpful for laser cutting) is that they are scalable without losing quality or detail. This means one design can be scaled up or down to make a variety of different products.

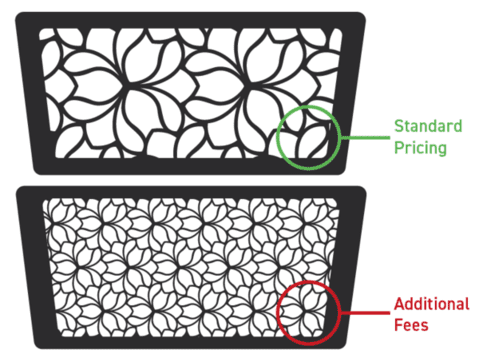

Don’t go too crazy: Sometimes less is more. When designing your art, jewelry, etc. make sure not to make the design too intricate. Excess cutting takes extra time and can cause problems in the material like warping. In this image, the example on top is great. The one on the bottom is a bit too intricate. Each material has its own guidelines for the level of detail to aim for, and it’s often based on thickness.

Design in a 1:1 ratio: This means, if you’d like your piece to be 3 inches tall and 6 inches wide, design it in exactly this size, not 1 inch tall and 2 inches wide. This makes it easier to know exactly what size your details are.

Bring Your Ideas and Business to Life with the Help of SendCutSend

Whether you’re looking to make a little extra income, or you’re a full-time Etsy seller, adding some extra products to your line can help you broaden your audience reach, and ultimately, make sales. With SendCutSend’s crazy-fast turnaround time, you’ll keep those stellar reviews rollin’ in and your customers coming back for more.