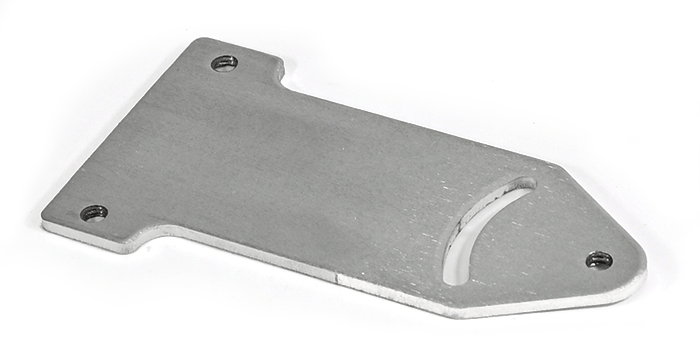

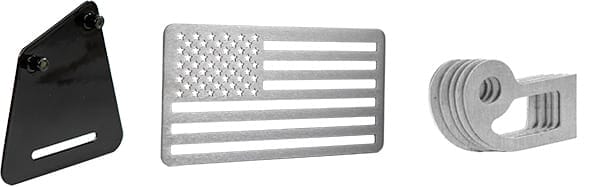

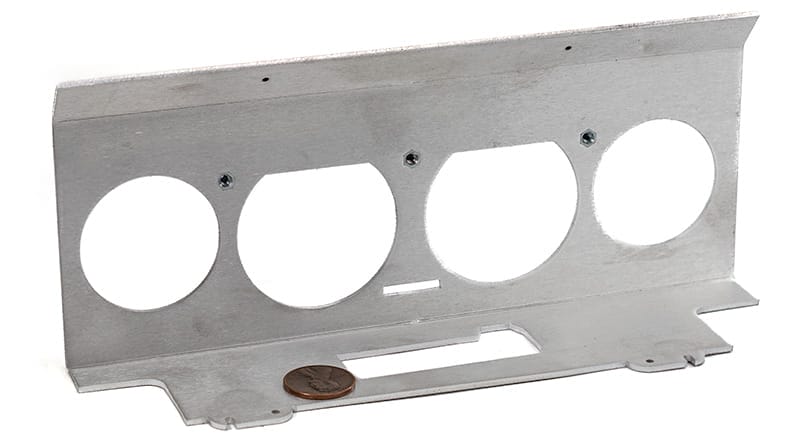

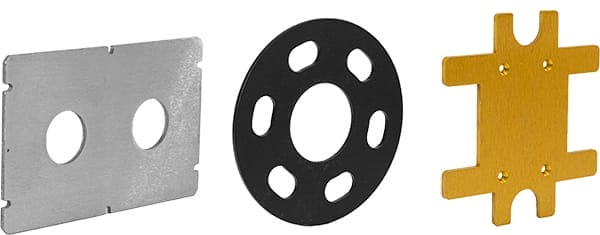

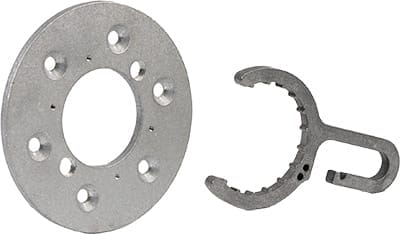

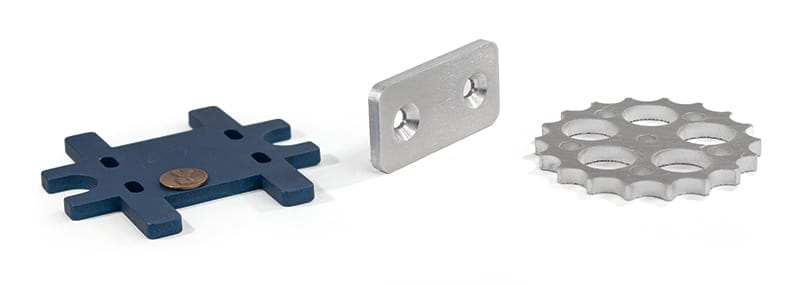

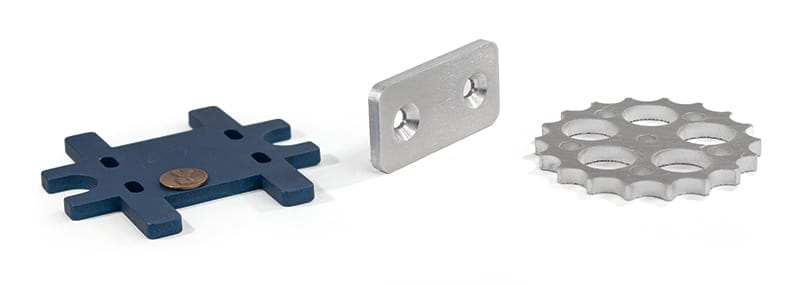

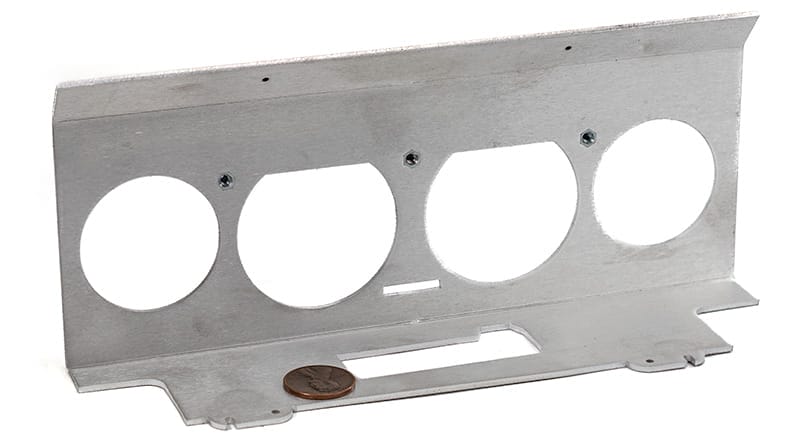

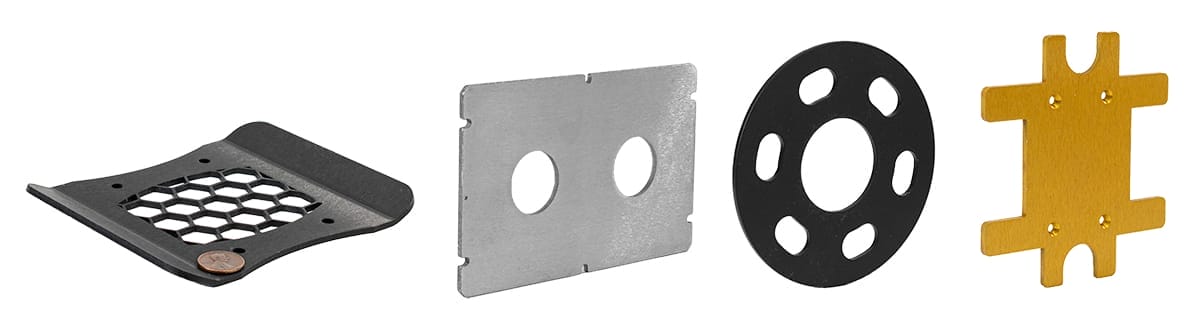

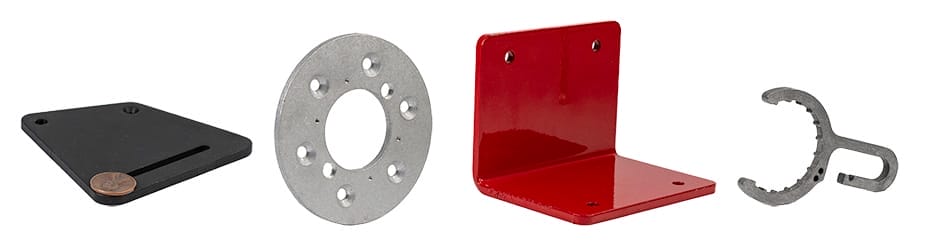

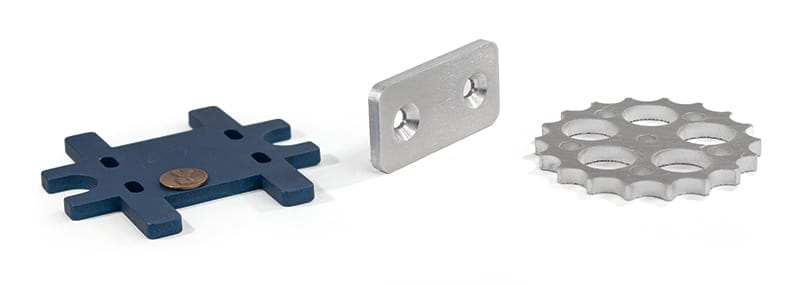

Corrosion resistant, strong, and durable, laser cut 6061 aluminum is ideal for a wide variety of applications across automotive, aerospace and robotics. 6061 aluminum is also known for its weldability while maintaining strong impact loading performance. So whatever your next custom laser cut project is, 6061 checks all the boxes.

6061 T6 Aluminum is strong and lightweight. Our laser cut 6061 aluminum is commonly found in structural applications where toughness and corrosion resistance are of high importance. That’s pretty typical for aluminum alloys in general, but what makes this 6061 series stand out is its heat-treatability. The heat-treating process, called precipitation hardening, further strengthens the alloy without robbing it of key properties.

Many of our aluminum alloys are able to withstand tremendous amounts of vibration (also known as fatigue strength) making them perfectly suited for high-impact applications such as transportation and robotics. For any of these applications 6061 aluminum is a good middle of the road alloy, pairing the strength of 7075 with the malleability of 5052.

We guarantee awesome quality parts. If you’re not 100% happy, we’ll give you a refund or remake on the spot – no questions, no hassle.

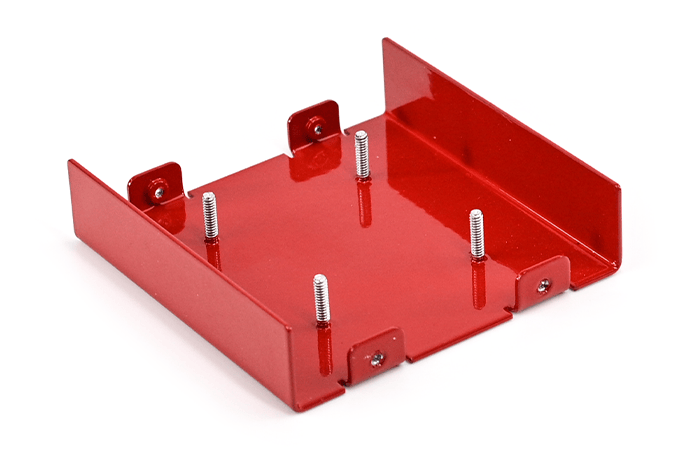

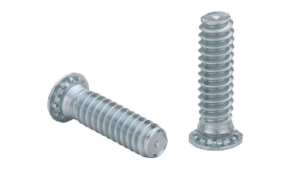

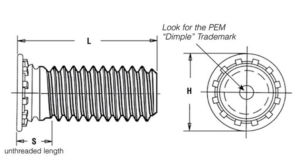

We proudly use hardware by PEM

Aluminum: 5052, 6061, 7075 Steel: Mild

| SKU | FH-M8-12 |

| Thread Size | M8 x 1.25 |

| Hole size in sheet (+0.003/-.0.000) | .315″ |

| Minimum sheet thickness | 0.094″ |

| Maximum sheet thickness | .347″ |

| Fastener material | Steel |

| Minimum distance hole C/L to edge | 0.378″ |

| Minimum distance between two of the same hardware | .567″ |

| Recommended panel material | Steel/Aluminum |

| Coating type | Zinc |

| Length | .472″ |

| Aluminum material ranges (5052, 6061, 7075) | 0.100″-0.250″ |

| Steel material ranges (CRS, HRPO, HR) | 0.104″-0.250″ |

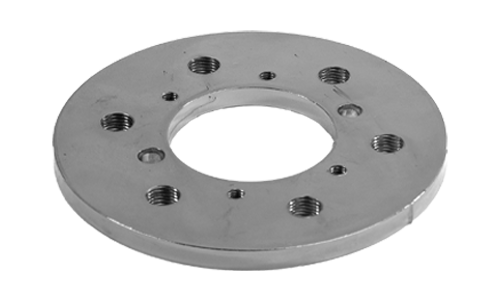

We proudly use hardware by PEM

Aluminum: 5052, 6061, 7075 Steel: Mild, G30

| SKU | SO-440-8 |

| Thread Size | 4-40 x .250″ |

| Hole size in sheet (+0.003/-.0.000) | .168″ |

| Minimum sheet thickness | 0.040″ |

| Maximum sheet thickness | .125″ |

| Fastener material | Steel |

| Minimum distance hole C/L to edge | 0.230″ |

| When determining the distance between two or more fasteners, you can calculate the distance by the formula, C/L to edge + 1/2 the diameter of the second mounting hole. | .345″ |

| Recommended panel material | Steel/Aluminum |

| Coating type | Zinc |

| Length | .250″ |

| Aluminum material ranges (5052, 6061, 7075) | 0.040″-0.125″ |

| Steel material ranges (CRS, HRPO, HR) | 0.048″-0.119″ |

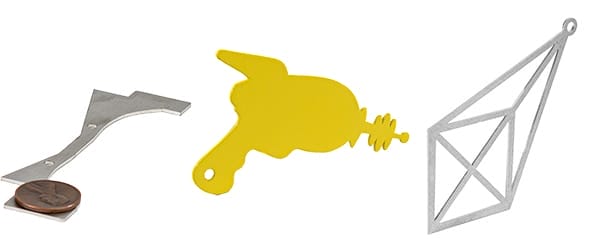

We proudly use hardware by PEM

Stainless Steel: 304, 316

| SKU | SO4-440-8 |

| Thread Size | 440 |

| Hole size in sheet (+0.003/-.0.000) | .166″ |

| Minimum sheet thickness | 0.04″ |

| Maximum sheet thickness | .125″ |

| Fastener material | 400 Stainless Steel |

| Minimum distance hole C/L to edge | 0.230″ |

| When determining the distance between two or more fasteners, you can calculate the distance by the formula, C/L to edge + 1/2 the diameter of the second mounting hole. Example shown with x2 of the same hardware. | .313″ |

| Recommended panel material | Stainless Steel |

| Coating type | Passivated |

| Length | .250″ |

| 304 Stainless Steel material ranges | 0.048″-0.125″ |

| 316 Stainless Steel material ranges | 0.060″-0.125″ |