No CAD? Customize a part template using our Parts Builder, or send a sketch to our Design Services team.

Prices based on factors such as materials and services. Shipping as low as $19 USD to Canada.

2-4 day transit times to Montreal, Vancouver, Toronto and other major cities. We collect all taxes and duties for quick and easy shipping.

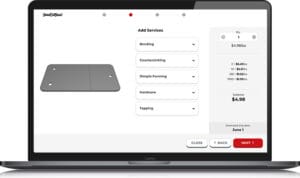

Upload a CAD file, send us a sketch, or use one of our templates.

Select a material and add operations and finishing. Prices update live.

Standard orders are out the door in 2-4 days

Parts shipping to Canada must be below freight requirements of 71 – 1,000 lbs and less than 44” x 30″

“Fast shipping, great pricing and almost too many options. 4 days to my door in Canada. My local options were more money and more time unless i wanted to pay a rush premium. The part builder is super nice too. Quicker than me messing around on AutoCad for the more simple parts. Check it out.”

3 thicknesses: .125" - .234"

2 thicknesses: .118" & .236"

6 thicknesses: .063" - .500"

1 thickness: .025"

11 thicknesses: .040" - .500"

12 thicknesses: .040" - .750"

CNC Machining

3 thicknesses: .125" - .250"

1 thickness: .250"

5 thicknesses: .119" - .500"

4 thicknesses: >.125" - .472"

1 thickness: .015"

5 thicknesses: .040" - .250"

6 thicknesses: .040" - .197"

1 thickness: .030"

5 thicknesses: .050" - .250"

5 thicknesses: .040" - .250"

2 thicknesses: .063" - .125"

1 thickness: .155"

2 thicknesses: .125" - .270"

5 thicknesses: .063" - .375"

5 thicknesses: .030" - .074"

1 thickness: .125"

3 thicknesses: .250" - .500"

2 thicknesses: .125" & .187"

3 thicknesses: .125" - .375"

4 thicknesses: .125" - .500"

12 thicknesses: .030" - .500"

2 thicknesses: .005" - .010"

2 thicknesses: .063" & .125"

2 thicknesses: .063" & .125"

2 thicknesses: .063" - .125"

3 thicknesses: .118" - .220"

3 thicknesses: .875" - 2.250"

1 thickness: .030"

10 thicknesses: .030" - .500"

4 thicknesses: .060" - .250"

1 thickness: .040"

5 thicknesses: .040" - .250"

2 thicknesses: .375" - .500"

1 thickness: .045"

2 thicknesses: .063" & .125"

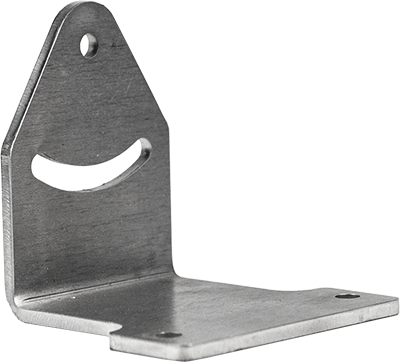

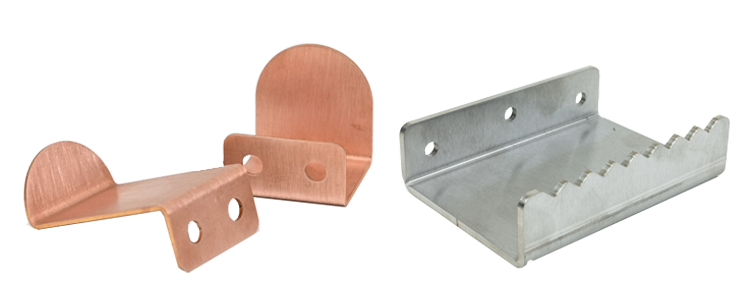

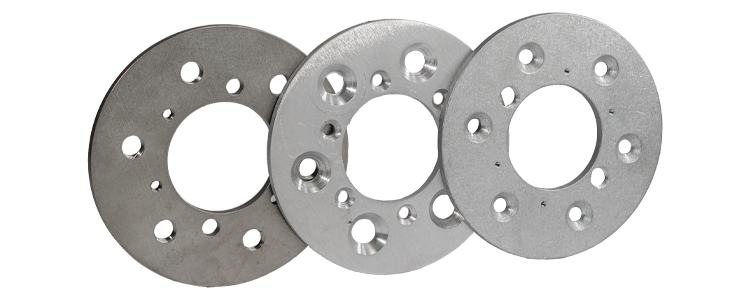

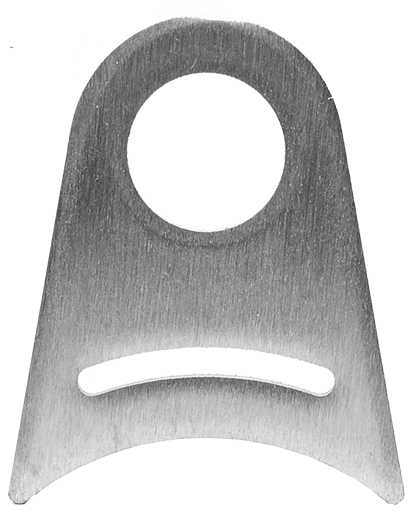

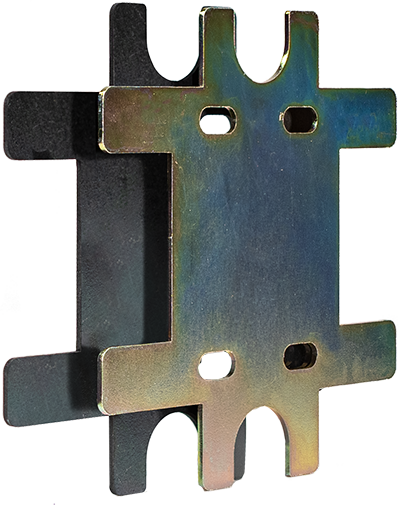

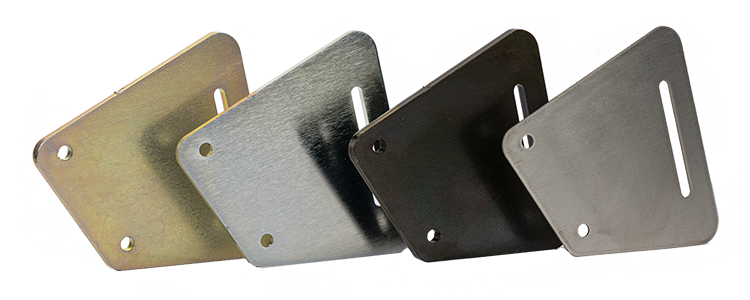

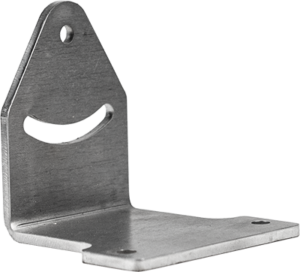

Custom laser cutting, waterjet cutting, and CNC routing. We’ll cut your parts with the method best suited for your sheet or plate material.

2-4 days standard production

Our fast laser tube cutting services deliver precisely manufactured parts in round, square, and rectangular tube metal materials.

2-4 days standard production

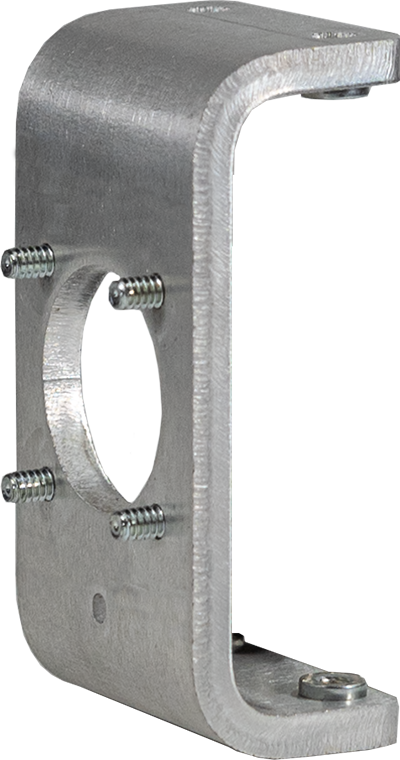

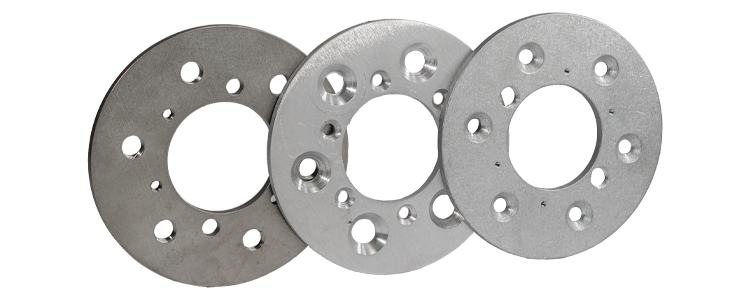

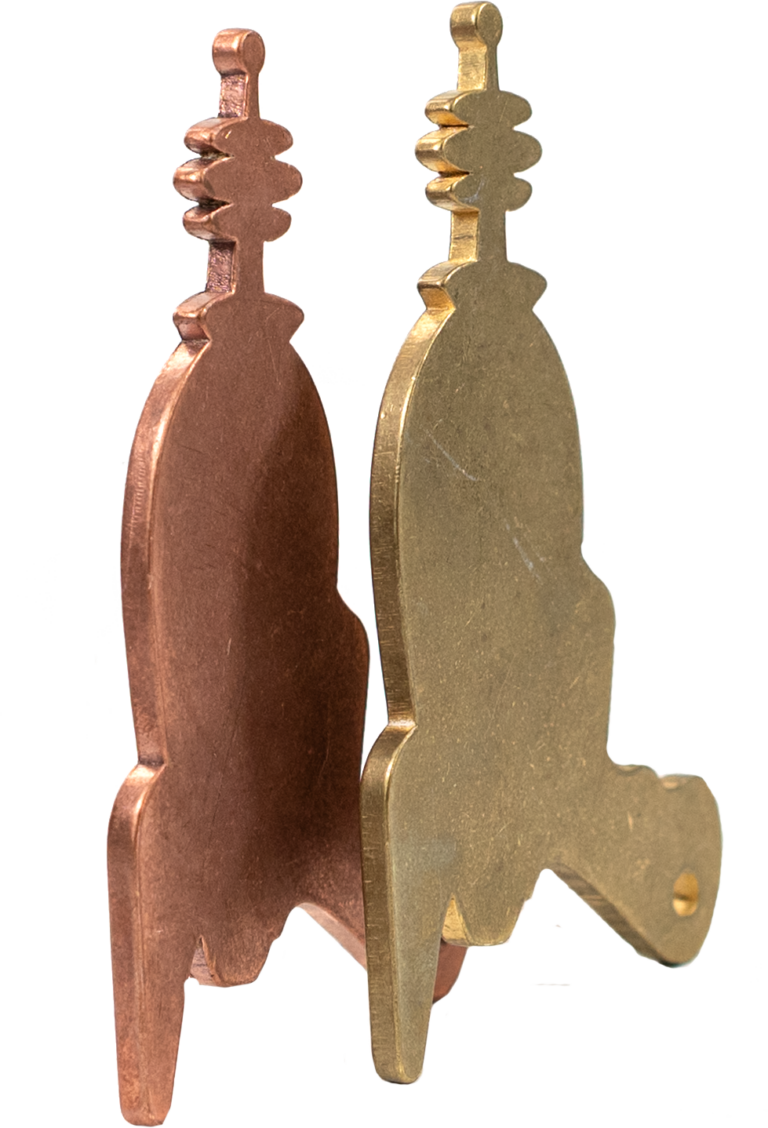

Multiaxis CNC machining in billet stock. This subtractive process uses precise machining to sculpt blocks of raw metal into nearly anything you can imagine.

2-4 days standard production

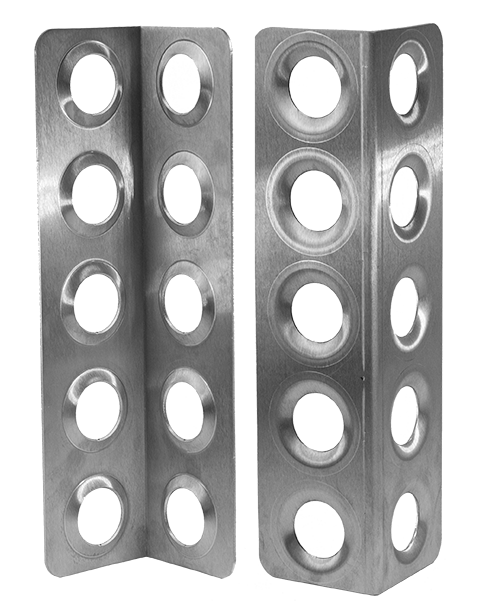

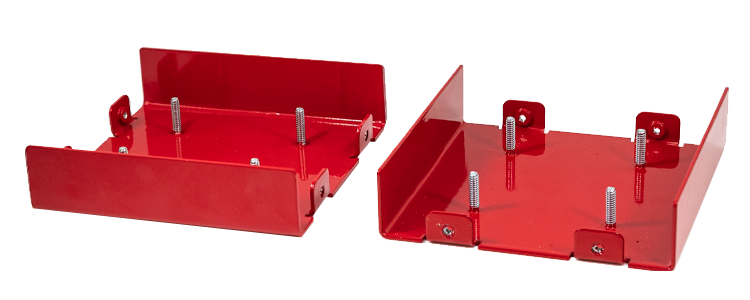

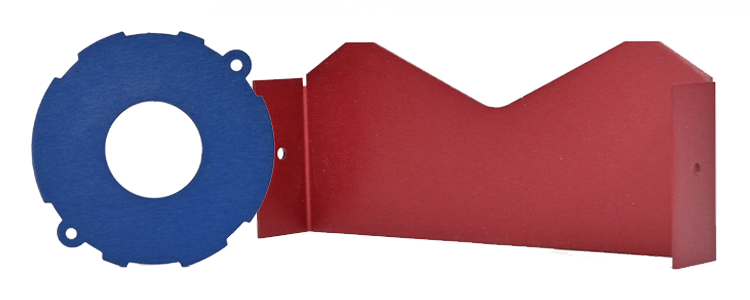

Add dimension to your projects with our precision CNC bending services.

+1-2 days | 10 materials

Allow hardware to sit flush on your parts to reduce wear and tear.

+1-3 days | 6 materials

Strengthen material with aesthetically pleasing dimples.

+1-3 days | 7 materials

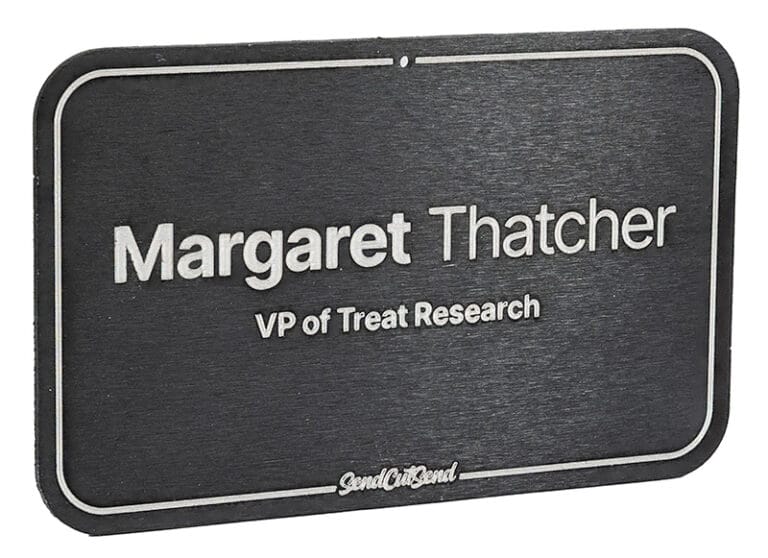

Easily add text and small details to your custom cut parts with our metal laser engraving services.

+1-3 days | 3 materials

Select from our catalog of PEM press-fit hardware to add nuts, studs, and standoffs.

+1-3 days | 8 materials

Quickly and easily add threading to allow for the addition of hardware to your parts.

+1-3 days | 13 materials

We offer Class II anodizing services to add durability and character to your laser cut parts.

+7-10 days | 4 materials

This process removes small imperfections, scratches, and burr left over from the cutting process.

+0 days | 8 materials

Increase rust prevention, wear resistance, and strength with zinc and nickel plating.

+7-10 days | 3 materials

Give your laser cut parts a bold, long-lasting finish and protective layer in one of 7 colors, 4 finishes

+3-5 days | 10 materials

Reduce the surface blemishes and handling scratches found in raw materials.

+1-2 days | 11 materials

Get started on your project with the click of a button. Whether you have a CAD file, a sketch, or just an idea.

Posted on

We take pride in our customer service, quality, and continual innovation with new products and services. You’re in good hands with SendCutSend.

We accept .ai, .dxf, .dwg, .eps, .stp, and .step

Customize one of our simple parts templates

Jim and Jake, our founders, experienced frustration with the time and money consumed in acquiring custom parts for their projects. Armed with expertise in software development, they launched SendCutSend as their solution.