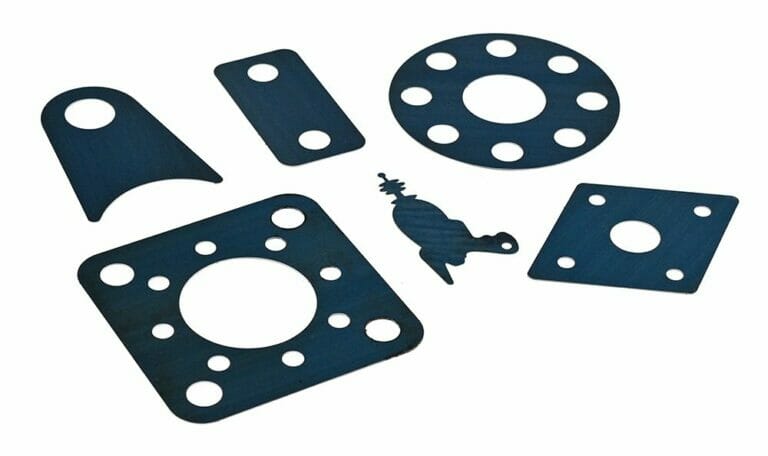

Relying on its superior tensile and yield strengths, 1075 spring steel is positioned as the essential material for spring, coil, and shim manufacturing. Our laser cut 1075 Blue Tempered Spring Steel (also known as Scaleless Blue Tempered Steel) is perfect for spring applications or where stiffness is required with minimal thickness.

Instant quote

A: .25″ x .375″

B: 13″ x 44″

Custom quote

C: 13″ x 56″

.015″ (.381mm)

1075 blue tempered spring steel is a type of high-carbon steel renowned for its exceptional resilience, strength, and durability. The “blue temper” refers to the process of heating the steel to a specific temperature and then cooling it rapidly to achieve optimal hardness and toughness. This steel is characterized by its ability to resist deformation and return to its original shape after being subjected to stress, making it ideal for applications requiring reliable spring properties.

1075 Blue Temper Spring Steel is a versatile steel that isn’t just for springs, clamps, and coils. It’s often used in blade-making as well. It’s able to hold its edge well and is receptive to sharpening. It also has much better workability and toughness than something with a higher carbon count (like 1095).

We source this high-demand metal through trustworthy suppliers with verifiable industry credentials so you don’t have to worry about it. You’ll know that our 5052 aluminum sheets are ready to be transformed into your greatest ideas.

Material certifications (PDF) are available below.

5052 Aluminum .040″

5052 Aluminun .063″

5052 Aluminum .080″

5052 Aluminum .100″

5052 Aluminum .125″

5052 Aluminum .190″

5052 Aluminum .250″

5052 Aluminum .375″

5052 Aluminum .500″

We guarantee awesome quality parts. If you’re not 100% happy, we’ll give you a refund or remake on the spot – no questions, no hassle.

SendCutSend offers Blue Temper Steel in one thickness option: .015″ (.381mm).

When working with Blue Temper Steel at SendCutSend, there are specific size and thickness parameters to keep in mind. For instant quoting, the smallest part size available is .25″ x .375″, while the largest part supported is 13″ x 44″. For larger projects, custom quotes are available for sizes up to 13″ x 56″.

SendCutSend’s 1075 Blue Temper Steel is not eligible for any secondary services.

We accept .ai, .dxf, .dwg, .eps, .stp, and .step

Customize one of our simple parts templates

When your design needs flexibility, fatigue strength, and reliable spring performance, 1075 blue temper spring steel delivers. It’s the go-to material when mild steel is too soft and stainless is too brittle — perfect for springs, clips, shims, and fasteners that flex repeatedly but must return to their original shape. At SendCutSend, we laser cut 1075 blue temper spring steel sheet to ±.005” tolerance, giving engineers, fabricators, and makers access to a durable, pre-tempered spring alloy that’s ready to perform right out of the box. This guide focuses on why fabricators choose 1075 for spring and tension applications, how it behaves under stress, and what to consider when designing with this hardened, tempered material.

1075 blue temper spring steel is a medium-high carbon steel that’s been hardened and tempered to balance tensile strength, spring tension, and toughness. It’s slightly less hard than 1095 but offers better ductility and shock resistance — ideal for dynamic parts that flex rather than fracture.

1075 spring steel offers a near-perfect balance of strength, flexibility, and fatigue life. It’s hard enough to resist deformation, yet ductile enough to endure repeated bending.

This material is engineered to store and release energy consistently. It flexes, snaps back, and holds its shape over thousands of cycles. That’s what makes 1075 indispensable for everything from precision clips and fasteners to shims, lock springs, and mechanical tension parts. In fabrication terms:

SendCutSend laser cuts 1075 blue temper spring steel to ±.005” tolerance. Its pre-hardened condition requires tight control of laser parameters, resulting in sharp, smooth edges with minimal burr or distortion.

Laser cutting leaves bright, clean edges that contrast attractively with the blue surface finish — ideal for visible or precision parts.

When designing parts in 1075:

See SendCutSend’s design guidelines for more DFM best practices.

1075 blue temper spring steel is widely used where flexibility and strength are both essential. Common applications include:

If it needs to flex without breaking or snap back into position, 1075 is an ideal fit.

Choose 1075 blue temper spring steel when your design demands high strength, fatigue resistance, and elastic recovery in a thin, compact part. It’s tougher and more forgiving than 1095, making it the preferred option for clips, shims, and mechanical springs that require precise tension and long service life. At SendCutSend, we laser cut 1075 blue temper spring steel with ±.005” accuracy, short 2–4 day lead times, and professional-grade edge quality. Whether you’re prototyping custom tension parts or producing spring components in volume, 1075 gives your design reliable, repeatable performance right out of the box.