You might know it as plexiglass, but SendCutSend’s laser cut acrylic plastic is here to meet the expanding needs of your projects. Our cast acrylic laser cutting service includes several colors and thicknesses. Parts are often used for display panels, equipment enclosures, templates and prototypes.

A: .187″ x .375″

B: 30″ x 44″

.118″ (3.0mm)

.177″ (4.5mm)

.214″ (5.4mm)

SendCutSend offers acrylic in 10 colors and three thickness options. Clear acrylic is available in .118″, .177″, and .214″ thicknesses. Red, yellow, green, blue, grey, black, white, and mirrored acrylic are available in the .118″ thickness only.

Transparency and translucency of our acrylic varies by color. If the amount or quality of light transmission is important for your project, we recommend ordering sample pieces to confirm if specific acrylic colors will work for your application.

Your acrylic parts will come with a removable film on each side to protect them during handling and transit. Your parts may come with different films, even if they are duplicates of the same part.

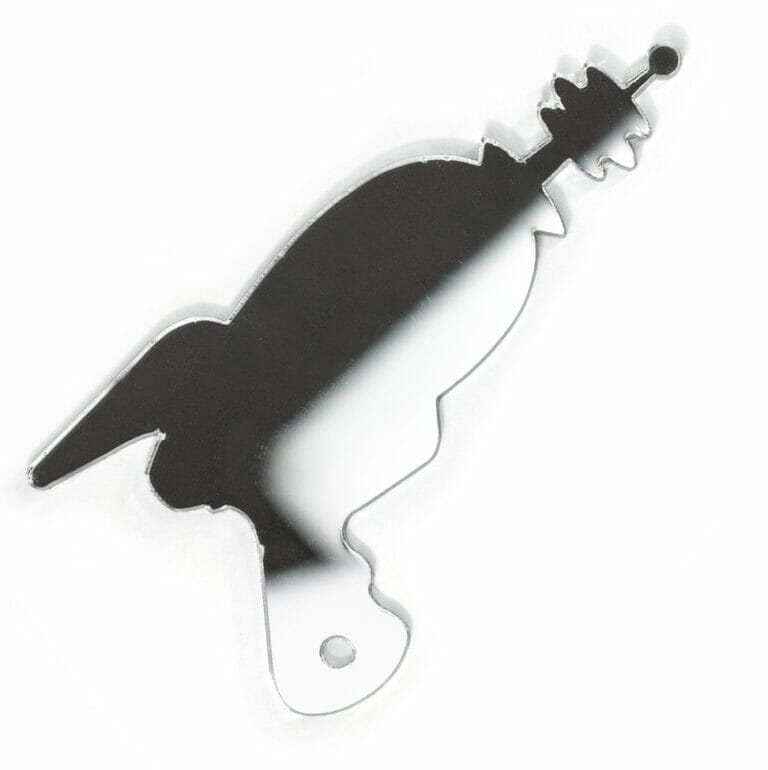

Mirrored acrylic will only have a protective film on the front side, while the back side is dull grey. We will cut your part mirrored side up. Our mirrored acrylic creates a true mirror without blur. The material is completely opaque.

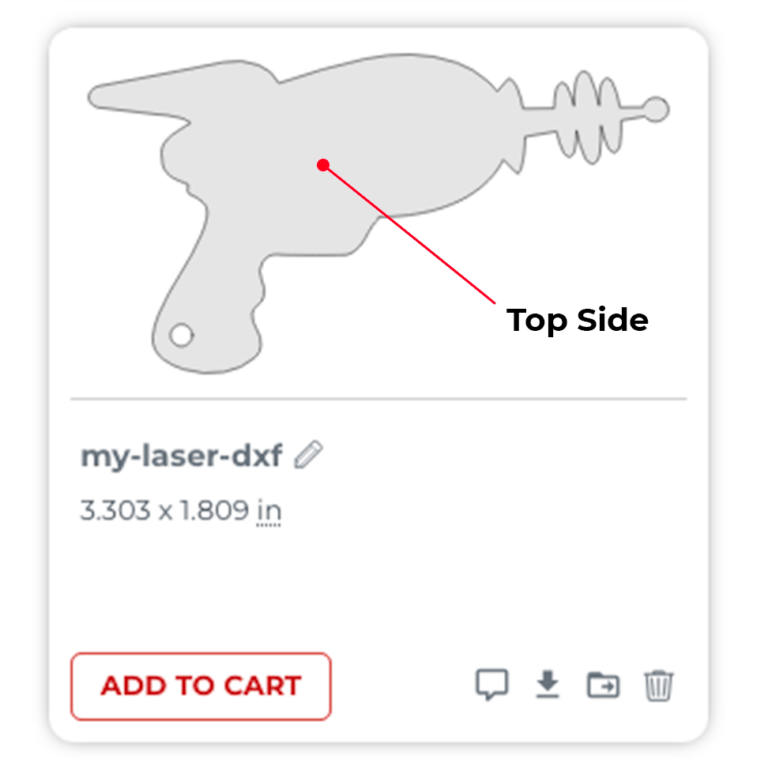

The orientation of your part as shown in the part preview will be considered the top side.

You may notice small tick marks on the underside of your parts. These marks are a normal part of the cutting process.

We like to refer to Acrylic as the wonder plastic. Originally used in World War II for airplane windows and canopies, acrylic has evolved to a plethora of new usages. Thanks to its exceptional strength-to-weight ratio, versatility, and weather resistance, acrylic has found success across many industries.

Acrylic is typically about 10 times more resistant to impact than standard glass.

Whether diffusing light in modern fixtures or offering protective barriers in medical settings, acrylic’s versatility shines through, rendering it a material of choice in numerous applications worldwide. Its innate properties, including optical clarity, lightweight nature, and exceptional durability, make it an ideal choice for a myriad of purposes.

We guarantee awesome quality parts. If you’re not 100% happy, we’ll give you a refund or remake on the spot – no questions, no hassle.

SendCutSend offers Acrylic in three thickness options: .118″ (3.0mm), .177″ (4.5mm), and .214″ (5.4mm).

When ordering custom Acrylic parts through SendCutSend, there are specific size and thickness parameters to keep in mind. For instant quoting, the smallest part size available is .187″ x .375″, while the largest part supported is 30″ x 44″.

You can add the following services to your Acrylic parts:

Laser Cutting

We accept .ai, .dxf, .dwg, .eps, .stp, and .step

Customize one of our simple parts templates

Send us a sketch or template and we'll create a file and send you a cart.

When you’re designing parts in acrylic—whether it’s for functional prototypes, consumer products, or creative projects—there are a lot of questions that come up. Acrylic is one of the most versatile plastics available, but it has very specific strengths, weaknesses, and best practices you’ll want to understand. Below you’ll find answers to the most common questions customers ask about acrylic, based on real-world design, fabrication, and application considerations.

Crystal Clarity: Acrylic transmits up to 92% of light, rivaling glass for transparency and aesthetics. Best for Laser Cutting: Cast acrylic cuts cleanly with flame-polished edges and engraves with a frosty-white finish. Strong but Brittle: 10× stronger than glass but more prone to cracking than polycarbonate under impact. Weather-Resistant: Naturally UV-stable, won’t yellow in sunlight, and lasts 10–15 years outdoors. Heat-Sensitive & Flammable: Softens around 160–190°F and is flammable—design accordingly.

One of the first questions people ask is about the difference between cast acrylic and extruded acrylic. They look similar at a glance, but the manufacturing process and resulting performance vary.

For high-precision laser cutting and engraving, cast acrylic is almost always the better choice which is why SendCutSend uses cast acrylic only.

Acrylic and polycarbonate are frequently compared because they’re both transparent plastics. Here’s how they stack up:

If your project values clarity and polished edges, acrylic is ideal. If you need impact resistance or heat resistance, polycarbonate may be better.

Yes, acrylic is naturally UV-stable. Unlike some plastics, acrylic won’t yellow noticeably in sunlight, even after years of exposure. That’s why acrylic is used in outdoor signage, aquariums, and architectural glazing. However, not all acrylic grades are created equal. Some formulations are more weather-resistant than others. While cast acrylic performs well outdoors, cheap extruded grades may craze or degrade faster. If your project is permanently outdoors, acrylic is usually a safe bet—but if you need maximum weathering resistance, specialty grades like UV-stabilized acrylic sheets may be preferable.

The decision comes down to volume, precision, and equipment access.

In short: if your project demands professional results and production-quality consistency, outsourcing is the more efficient and cost-effective route. If you’re tinkering or testing ideas, cutting at home can be a fun way to learn—but it won’t match the precision or scalability of professional fabrication. If you’re ready to get acrylic parts cut at SendCutSend, review our design guidelines for the best results.

Most acrylic sheets come with protective masking on both sides to prevent scratching during handling. When laser cutting, it’s generally best to leave the masking on—especially if it’s paper-based.

At SendCutSend, we cut acrylic with the correct settings so masking doesn’t interfere with precision. Keeping masking in place until you’re ready to use the part ensures you receive scratch-free, polished components.

This is a big question. Traditionally, CO₂ lasers are used to cut acrylic, because their 10.6 µm wavelength is strongly absorbed by the plastic. Fiber lasers, however, operate at around 1.06 µm—wavelengths that clear acrylic naturally transmits. That means clear acrylic doesn’t absorb fiber laser energy efficiently and can be very difficult to cut. SendCutSend uses advanced laser setups to process acrylic, but in general, if you’re cutting acrylic yourself, CO₂ lasers are the preferred method. Fiber lasers are much better suited to metals.

Yes, acrylic does release emissions when laser cut but compared to some plastics, they’re relatively manageable. When cut, acrylic produces fumes that are primarily methyl methacrylate monomer (MMA) vapor. These fumes have a strong odor but are not as toxic as PVC or polycarbonate fumes. Still, you must use proper ventilation and exhaust systems when laser cutting acrylic. Good airflow keeps cuts clean and ensures operator safety. At SendCutSend, our industrial exhaust systems handle this automatically so the end user only receives clean, safe acrylic parts.

Laser cutting always removes a small amount of material—this is called the kerf. With acrylic, kerf width is influenced by laser power, focus, and material thickness. At SendCutSend, our acrylic cutting tolerance is ±.009”. That means if you need parts to press-fit together, you’ll want to account for kerf when designing slots, tabs, or interlocking features. As a rule of thumb:

Because acrylic is rigid but brittle, placing holes or slots too close to the edge can create stress points that lead to cracking.

Adding corner fillets and rounding edges near holes can improve crack resistance significantly.

Yes. Fillets (rounded corners) are highly recommended when designing acrylic parts. Sharp internal corners concentrate stress, which can cause cracks to propagate under load. By adding even a small radius (e.g., 0.02”–0.05”), you spread the stress more evenly. This makes your acrylic part more durable and less prone to fracture during use or assembly. This design-for-manufacturing step costs nothing in CAD but can extend the service life of your part.

It is possible to cut threads in acrylic, but it must be done carefully:

That said, threads in acrylic are inherently fragile. For any application where the screw will be removed or adjusted frequently, it’s better to use threaded brass inserts or through-holes with metal hardware.

The gold standard for acrylic bonding is solvent cement. This adhesive works by softening the acrylic surfaces so they fuse together as the solvent evaporates.

For best results:

Done correctly, the resulting joint can be nearly as strong as the acrylic itself, with excellent optical clarity.

Bonding acrylic to dissimilar materials requires different adhesives:

Always check the adhesive’s datasheet for compatibility and test on scrap material first. When possible, mechanical fasteners are more reliable for acrylic-to-metal joints.

Yes, acrylic can be bent using controlled heat. The key is temperature:

Acrylic will retain its new shape once cooled, but residual stress can remain. If precision and durability are critical, parts may need annealing to relieve stress after bending.

Most cast acrylic is considered food-safe once fully polymerized, but only for incidental contact. It is not FDA-approved for prolonged food contact like cutting boards or beverage containers. Acrylic is often used for sneeze guards, food display cases, and protective covers in food environments. For direct, long-term food contact, you’ll want to verify the acrylic’s certification or select an FDA-approved grade.

No, acrylic is not naturally flame-retardant. In fact, it is flammable and will burn if exposed to an open flame or high heat. When burning, it releases carbon dioxide, water, and carbon monoxide. If you need flame-retardant plastic, materials like polycarbonate or specialty FR acrylic sheets are better suited. Acrylic should not be used near heat sources or in environments where fire safety is critical.

Yes, temperature extremes can affect acrylic:

The safe continuous-use temperature for most acrylic grades is 160–190°F (70–90°C). For outdoor installations in freezing climates, design with added thickness or consider polycarbonate if impact resistance in cold weather is critical.

Acrylic is one of the most weather-resistant plastics available. It resists UV light, humidity, and thermal cycling better than many alternatives. Over time, however, outdoor exposure can still lead to:

With proper design and occasional cleaning, acrylic can last 10–15 years outdoors with excellent optical clarity.

Acrylic is a premium plastic for laser cutting because it combines optical clarity, crisp laser-cut edges, and versatility. It’s not indestructible—it’s brittle, flammable, and sensitive to stress—but with proper design and assembly techniques, it can produce long-lasting, professional-quality parts. By understanding kerf allowances, adhesive compatibility, thermal limits, and outdoor durability, you can avoid costly mistakes and get the most out of your acrylic designs. At SendCutSend, we provide cast acrylic in multiple colors and thicknesses, laser cut to precision tolerances, with turnaround times designed for professionals, hobbyists, and businesses alike.