Our gasket grade sheet cork is manufactured with one clear goal in mind: creating a seal that you can trust. Rubber-bonded with oil, solvent, and petrol resistances, you can trust your cork gaskets, seals, and panels to be leak-free and durable. It even seals well at low flange pressures and high temperatures.

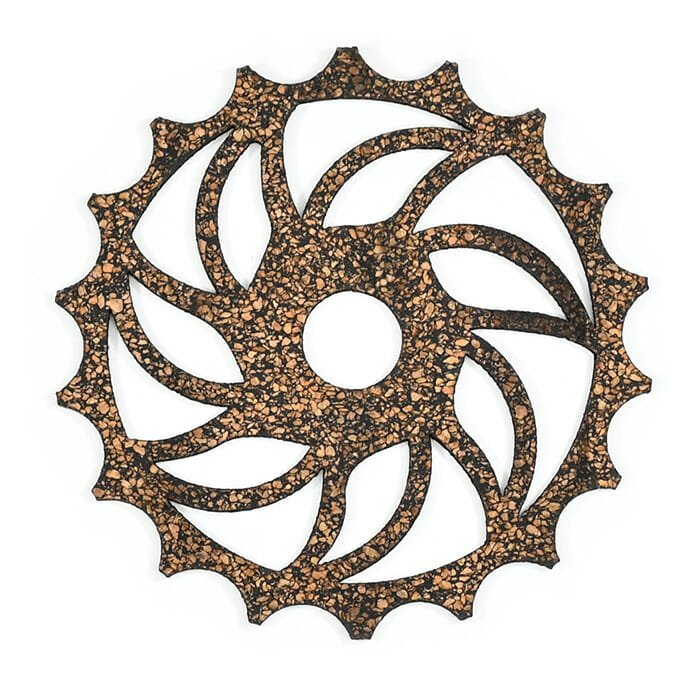

In addition to its many automotive, plumbing, and machining applications, sheet cork can also be used in decorative and aesthetic functional projects. From laser cut cork bulletin boards to coasters to home organization tools, sheet cork deserves a place in your next project.

We guarantee awesome quality parts. If you’re not 100% happy, we’ll give you a refund or remake on the spot – no questions, no hassle.

SendCutSend offers Cork (gasket grade) in two thickness options: .063″(1.6mm), and .125″(3.18mm)

With SendCutSend’s Cork (gasket grade) offering, you can get parts instantly quoted if they fall between 1″ x 1″ and 30″ x 34″.

You can add the following services to your Cork (gasket grade) parts:

Laser Cutting

We accept .ai, .dxf, .dwg, .eps, .stp, and .step

Customize one of our simple parts templates

Gasket Grade Cork is a specialized type of cork material formulated for precision and durability in sealing applications, particularly where flexibility, compressibility, and chemical resistance are critical. Derived from cork oak bark and processed into sheets, it excels in forming tight seals and absorbing energy, making it ideal for various engineering and mechanical uses.

Laser cutting offers a suite of advantages for producing cork gaskets and custom components:

The two most effective laser types for cork are:

SendCutSend uses CO2 lasers to cut Gasket Grade cork, balancing speed and quality for sheet thicknesses up to .125”/3.18mm

At SendCutSend we can process several 2d vector files and 3D file formats for custom Gasket Cork laser cutting.

Thicker cork requires higher power for clean cuts; it’s best to use lower power and higher speed for thin sheets to minimize discoloration but increase power for thicker sheets. For especially thick cork, multiple passes may be needed. SendCutSend laser cuts cork in two thicknesses; .063”(1.60mm) and .125”(3.18mm).

You should consider DIY laser cutting for projects that are small, simple, and don’t require high precision or quality control. Examples include:

A home laser cutter (diode or entry-level CO2) can suffice for thin cork sheets, allowing quick results and low setup costs.

For large-scale, intricate, or industrial applications, outsourcing is ideal:

SendCutSend offers expertise in material selection, optimal settings, CAD conversion, and can guarantee precision at speed, minimizing error and waste.

Gasket grade cork is widely used for engine and transmission seals, including oil pan seals/gaskets, valve covers, and timing cover gaskets, due to its compressibility, resistance to oil and gasoline, and vibration damping properties.

Gasket grade cork is employed as a sealing material for pipes, flanges, pumps, and valves, where leak prevention and temperature resistance are critical.

Cork’s insulating properties make it a material of choice for sealing and vibration damping in sensitive electronic enclosures, reducing risk of short circuits and protecting against environmental ingress.

Often used under flooring for sound insulation, in expansion joint fillers, and as gasket material in doors and windows.

Due to its ability to form clean seals that do not absorb liquids, cork gaskets are used in food processing equipment and bottling machinery.

Applications in sealing and insulation for bulkheads, hatches, and vibration-dampening pads. Its resistance to water and ability to conform to complex shapes are valued in these settings.

Used for oil seals, fluid manifolds, instrumentation enclosures, chemical apparatus, and more, wherever fluid containment and shock absorption are required.

Laser cutting often leaves edges darkened by oxidation. This residue can generally be removed:

If seeking help for your specific application, contact reputable third-party laser cutting services with your requirements, design files, and usage context. Professional providers can recommend the right cork material, cutting parameters, and finish to deliver quality at speed and scale.