A36/A1018 HRP&O sheet metal is a versatile and highly sought-after material in various industries. Known for its excellent strength and durability, this hot rolled pickled and oiled steel is ideal for applications requiring robustness and reliability.

Instant quote

A: .25″ x .375″

B: 30″ x 44″

Custom quote

C: 30″ x 56″

.187″ (4.75mm)

.250″ (6.35mm)

HRP&O steel is much smoother and easier to finish than the cheaper “mill finished hot-roll” that most steel centers sell. HRP&O is just hot-rolled steel that is subjected to an acid bath to remove scale mill. Then it has some dry oil applied to prevent rusting. Overall, it has a nicer finish.

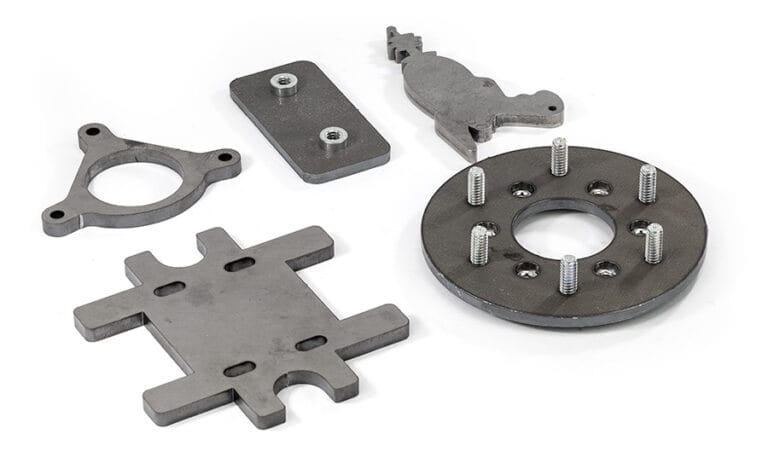

With A36/A1018 HRP&O sheet metal, you can fabricate a wide array of products including structural beams, automotive components, machinery parts, and industrial equipment. Its superior formability and weldability make it ideal for creating frames, brackets, supports, and enclosures. Additionally, its robustness and durability allow for the manufacturing of load-bearing structures and components that require high strength and resilience, ensuring reliability and longevity in demanding applications.

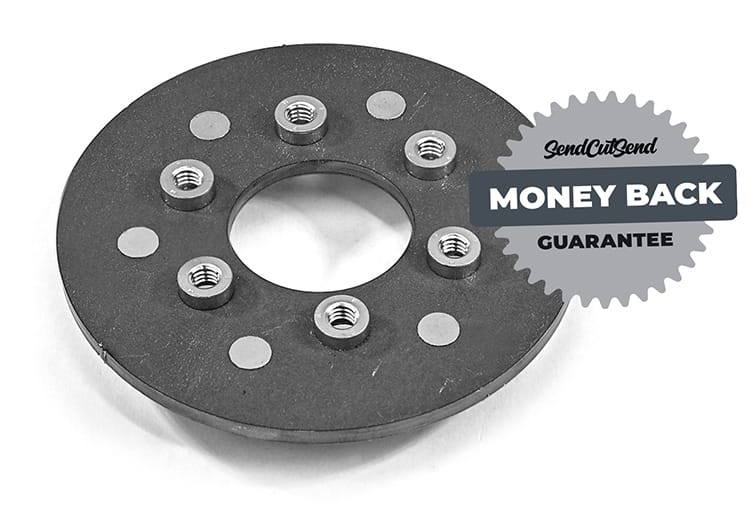

We guarantee awesome quality parts. If you’re not 100% happy, we’ll give you a refund or remake on the spot – no questions, no hassle.

Thicknesses offered include two variations including .187″(4.75mm) and .250″(6.35mm).

At SendCutSend, HRP&O Carbon Steel is supported with both instant and custom quoting depending on part size. The smallest part allowed is .25″ x .375″, while instant quotes go up to 30″ x 44″. For dimensions up to 30″ x 56″, a custom quote is needed.

You can add the following services to your HRP&O Carbon Steel parts:

Bending, Dimple Forming, Hardware Insertion, Plating, Powder Coating, Tapping, and Tumbling

We accept .ai, .dxf, .dwg, .eps, .stp, and .step

Customize one of our simple parts templates

A36/A1018 HRP&O combines the strength of A36 with the tight thickness and surface control of A1018 giving you the best of both worlds. It’s strong, consistent, and ideal for parts requiring laser cutting, bending, and hardware installation without the rough mill scale of hot rolled steel.

A36/A1018 is a blended specification combining two ASTM standards to create a versatile, high-strength mild steel with tighter dimensional control. This material is ideal when you want the reliable weldability and toughness of A36 but with the smoother finish and consistency of cold rolled or A1018 steel.

It shares much of A36’s strength but with improved consistency and surface condition. Typical properties:

This combination makes A36/A1018 an ideal sheet material for precision fabrication, brackets, and welded assemblies.

A36/A1018 laser cuts with excellent accuracy and smooth edges.

See our Design Guidelines for cutting and feature size recommendations.

Yes, SendCutSend offers bending services on HRP&O. This steel bends and forms cleanly without flaking or cracking.

Refer to our Bending Guidelines for geometry tips.

A36/A1018 accepts all common fabrication processes.

Before adding secondary services to your HRP&O parts, reference our service and design guidelines.

A36/A1018 HRP&O delivers the strength of structural steel with the surface quality and precision of sheet metal. SendCutSend laser cuts it to ±.005″ tolerance and offers full finishing options — making it an excellent choice for high-performance, high-accuracy parts. Explore all mild steel grades in our Material Catalog.