Strong enough to meet your needs with a host of specialized electrical properties, low water absorption, and fire retardancy, G-10 FR-4 grade is the go-to material for your electronic parts, robotics endeavors, and marine applications.

Instant quote

A: 1″ x 2″

B: 30″ x 44″

Custom quote

C: 30″ x 46″

.063″ (1.60mm)

.125″ (3.18mm)

.250″ (6.35mm)

.375″ (9.5mm)

These tabs hold your parts in place while being cut to ensure the best accuracy possible. Click below to learn what to expect and how to best design with these tabs in mind.

Our G-10 is made up of a mixture of epoxy resin and glass cloth, so you know it’s got strength under pressure. With superior electrical insulation properties, when both wet and dry, it’s the most widely used insulator for electrical applications in the industry. It boasts incredibly high mechanical strength and rigidity and has excellent dimensional stability over a wide temperature range, along with low water absorption rates.

Honestly, G-10 FR-4 is used most often in laminate circuit boards, but it does have a great many uses including insulating washers and transformer components. You’ll also find it used in firearm and knife grips due to its ability to take texture and color well. Any time you’re interacting with consumer electronics, you can assume that you’re in the vicinity of G-10 somewhere.

If you need something to get wet and be lightweight while doing it, G-10 is the material for you. Often used in marine applications for housings and electronic components, this versatile composite is able to withstand harsh marine environments. Some spearfishermen even use it as the primary material for their spear guns due to its lightweight nature and low water absorption.

Machining G-10 FR-4 parts can be challenging for some, but that’s why you come to SendCutSend with your designs, you can trust us to handle the heavy lifting for you and let you focus on the big picture.

We guarantee awesome quality parts. If you’re not 100% happy, we’ll give you a refund or remake on the spot – no questions, no hassle.

This material is available in four thickness options: .063″ (1.63mm), .125″ (3.18mm), .250″ (6.35mm), and .375″ (9.5mm).

SendCutSend cuts G10/FR-4 in a several sizes and thicknesses. Instant quoting is available for parts as small as 1″ x 2″ and as large as 30″ x 44″. Larger parts, up to 30″ x 46″, can be ordered through a custom quote.

You can add the following services to your G10/FR-4 parts:

Waterjet Cutting

We accept .ai, .dxf, .dwg, .eps, .stp, and .step

Customize one of our simple parts templates

Send us a sketch or template and we'll create a file and send you a cart.

Top 5 must‑know things about G-10

G‑10 is a high‑pressure fiberglass laminate created by stacking multiple layers of glass cloth soaked in epoxy resin and compressing them under heat. FR‑4 is the flame‑retardant variant of G‑10, commonly used in printed circuit boards and electrical applications. Both materials are prized for their strength‑to‑weight ratio, dimensional stability, and insulation properties. At SendCutSend, G‑10 is offered in four thicknesses and precision‑cut using waterjet technology to avoid heat damage and ensure clean, accurate cuts.

G‑10 and FR‑4 are structurally similar fiberglass‑epoxy laminates. The key difference: FR‑4 is flame‑retardant and meets UL 94V‑0 standards, making it suitable for electrical applications requiring fire resistance.

G‑10 offers exceptional mechanical strength, with tensile strength around 40,000 psi and flexural strength exceeding 60,000 psi. This makes it stronger than many plastics and competitive with some light metals.

Yes. G‑10/FR‑4 has a high dielectric strength (typically 500+ volts/mil), making it a go‑to material for insulators, circuit boards, and electrical housings.

G‑10/FR‑4 maintains stability up to around 130–140°C (glass transition temperature). It can briefly withstand higher temps, but prolonged exposure above Tg can cause degradation.

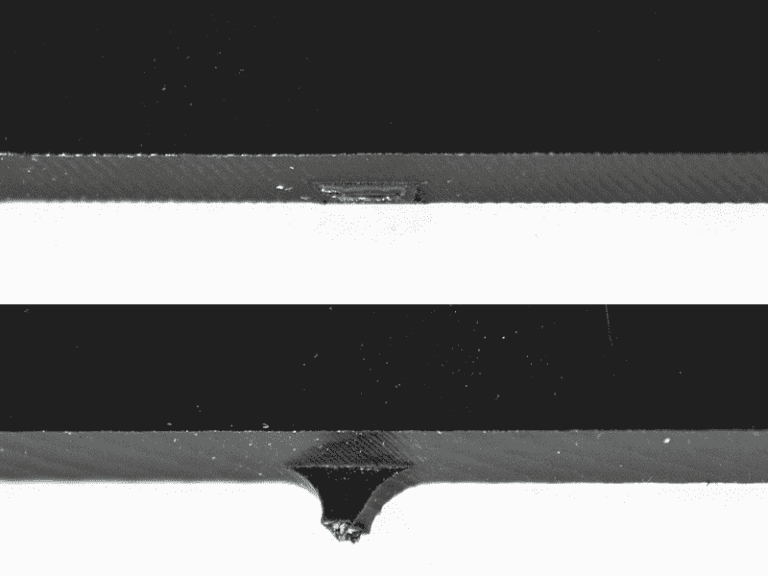

No—laser cutting G‑10 releases toxic fumes and produces charred edges. That’s why SendCutSend uses waterjet cutting, which avoids heat and delivers precision edges.

SendCutSend delivers ±0.009” cutting tolerance for G‑10 via waterjet, suitable for high‑precision applications.

Waterjet cutting leaves a clean, precise edge. Unlike mechanical cutting, there’s no risk of tool chatter or delamination, though edges may be slightly textured.

It’s possible but not recommended. Cutting generates abrasive fiberglass dust that can damage tools and harm lungs. Always use carbide tooling, dust extraction, and PPE.

No,G‑10 is moisture resistant, maintaining strength and insulation even in humid or marine conditions.

G‑10 has good weather resistance but can degrade with prolonged UV exposure. For outdoor use, coatings or paint may extend service life.

G-10 has high mechanical strength and rigidity with excellent stability over a wide temperature range. This combined with its low water absorption rates make it a common choice for the following industries:

Applications include PCB substrates, insulating components, bushings, spacers, and tool fixtures.

Both are strong composites, but carbon fiber is lighter and stiffer. G‑10 is less expensive, tougher under impact, and electrically insulating (carbon fiber is conductive).

G‑10 is lighter and electrically insulating, with better corrosion resistance. Aluminum is stronger under load and more heat‑resistant. Choice depends on application needs.

FR‑4 grade is flame retardant and UL 94V‑0 rated, meaning it self‑extinguishes once a flame source is removed.

SendCutSend currently offers G‑10 in one standard color (black). Custom colors may be available through specialty suppliers.

No, G‑10 is not FDA‑approved for food contact. It’s mainly for industrial, mechanical, and electrical applications.

Yes. Epoxies, cyanoacrylates, and mechanical fasteners all work well with G‑10.

With proper use, G‑10 parts can last decades. It resists wear, corrosion, and moisture—ideal for long‑term industrial and structural applications.