Prototyping with our laser cut hardboard will help ensure your product’s success before you ever place a full production run. Durable, workable, and affordable, laser cut hardboard will change the way you prototype and save you money simultaneously.

A: .25″ x .375″

B: 30″ x 44″

.125″ (3.18mm)

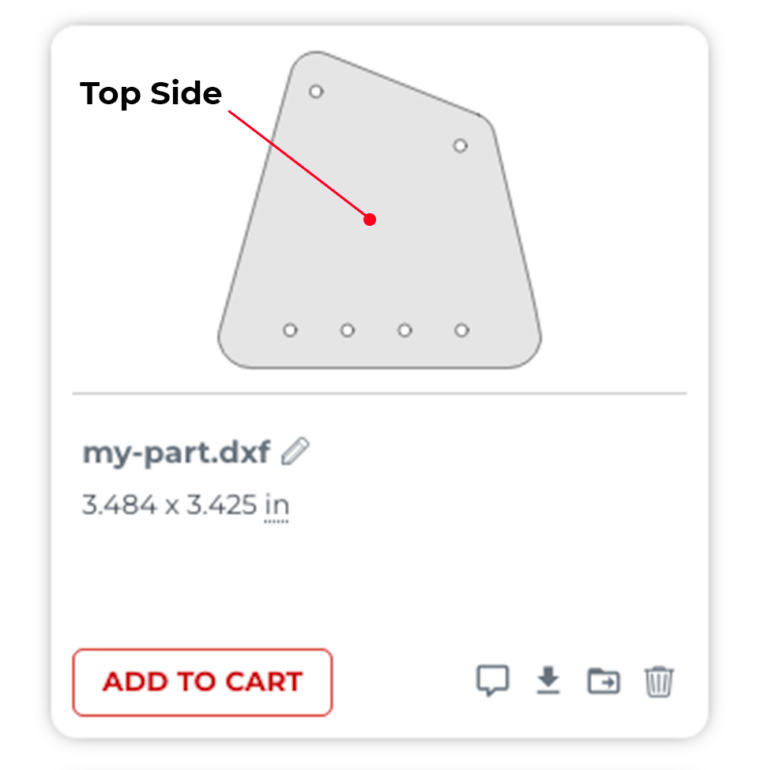

Please note (especially for mirroring parts), the finishes on the front and back may differ. The top side is smooth and the back will be textured. We will cut your file smooth side up.

The orientation of your part as shown in the part preview will be considered the top side.

Prototyping with our laser cut hardboard will help ensure your product’s success before you ever place a full production run. Durable, workable, and affordable, laser cut hardboard will change the way you prototype and save you money simultaneously.

Hardboard parts are limited only by your imagination. One of the best applications for laser cut hardboard is in prototyping. With its warping resistance and comparatively high strength, hardboard can be used to prototype any number of potential parts and products.

With 0.009” tolerance on our CO2 lasers, we’re able to cut your parts with high accuracy, getting your prototypes as close as possible to the “real thing.” We recommend placing a small order with several test parts, and thanks to the affordability of hardboard, you don’t have to worry about needing quantity discounts to come in under budget.

Once you’ve received the test parts and are pleased with the design, check out our other high quality materials and get a quote on your full production run!

We guarantee awesome quality parts. If you’re not 100% happy, we’ll give you a refund or remake on the spot – no questions, no hassle.

SendCutSend offers Hardboard in one thickness option: .125″(3.18mm).

When ordering Hardboard parts through SendCutSend, there are specific size and thickness parameters to keep in mind. For instant quoting, the smallest part size available is .25″ x .375″, while the largest part supported is 30″ x 44″.

You can add the following services to your Hardboard parts:

Laser Cutting

We accept .ai, .dxf, .dwg, .eps, .stp, and .step

Customize one of our simple parts templates

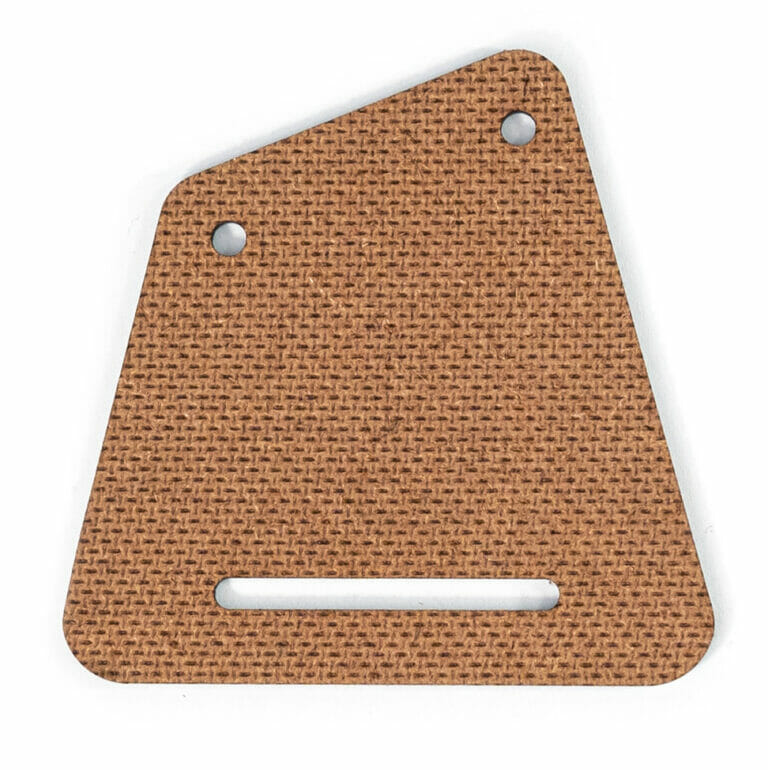

Hardboard (often called HDF or high-density fiberboard) is a dense, smooth, uniform wood fiber sheet frequently used for jigs, templates, backings, fixtures, signage, and craft work. Unlike MDF, hardboard is pressed without added resin binders, resulting in a tougher, more flexible, and more impact-resistant panel. Hardboard is ideal for laser cutting thin, stable wood parts. At SendCutSend, we laser cut globally-sourced .125” hardboard to ±.009” precision, producing clean, reliable parts for designers, makers, engineers, and fabricators.

Hardboard is chosen because it strikes a balance between cost, stability, and cut quality. It’s denser and smoother than MDF, more reliable than cardboard, and far cheaper than plywood — making it an ideal material for:

Fabricators like hardboard because it maintains its shape, doesn’t splinter, and cuts evenly across the entire sheet. Makers choose it because it’s inexpensive, forgiving, and finishes beautifully.

Hardboard is generally excellent for laser cutting, resulting in high-quality completed laser-cut parts. Here’s what to expect: Clean, consistent edges Hardboard laser cuts very cleanly due to its dense, uniform fiber composition. Moderate edge darkening Laser cutting leaves dark brown edges, similar to MDF. This is normal and expected for fiberboard. Smooth surface with minimal burn marks Most burn residue wipes off with a cloth or light sanding. Very fine detail possible Because there is no grain direction, small internal features cut cleanly. No voids or blowouts Unlike plywood, hardboard has no internal gaps, so cut quality is consistent across the sheet. Hardboard is one of the most reliable wood-based materials for laser-cutting small details or thin features.

Hardboard has one of the cleanest surfaces of any sheet wood product, making it ideal for:

This gives hardboard predictable performance when laser cutting and prevents grain-related tear-out found in plywood.

Hardboard is significantly less expensive than birch plywood or hardwood sheets, making it perfect for:

Unlike MDF, hardboard bends slightly without snapping. This makes it more resistant to impact and suitable for parts that need minor flex.

Hardboard remains flat across its surface and is resistant to warping under normal indoor conditions.

Hardboard absorbs water and will swell or warp if exposed to moisture. For outdoor or wet environments, consider:

While hardboard cuts cleanly, thick engraving or slow cutting can darken or scorch the surface.

Hardboard is not available in varying thicknesses; it’s a thin, utility-oriented material.

Hardboard is not suitable for load-bearing parts or high-strength assemblies.

Screws can split the board if over-tightened. It’s best used for glued or lightly fastened assemblies.

Design considerations for hardboard center around its thin profile and dense fiber structure.

Avoid extremely thin “fingers”: Features thinner than 0.08″–0.10″ can be fragile. Use fillets to prevent cracking: Rounded inside corners reduce stress concentration. Consider kerf and edge darkening: Laser kerf is consistent, but friction-fit parts may require minor adjustment. Allow for fragile edges: Avoid placing extremely small holes or notches near part corners. Paint or seal after cutting if needed: Hardboard accepts paint well, but sealing also helps resist humidity. Check out SendCutSend’s design guidelines for more tips on how to prepare your file for cutting with SendCutSend.

Hardboard is widely used in woodworking, crafting, laser cutting, prototyping, and industrial design. Some common applications include:

Its stability and low cost make it a go-to material for both prototypes and production craft items.

Choose hardboard when you need a thin, smooth, affordable fiberboard that cuts cleanly with a laser and is ideal for:

Hardboard is perfect when the priority is price, cut quality, and surface finish, but not strength, moisture resistance, or outdoor performance. SendCutSend laser cuts .125” hardboard with ±.009” precision and 2–4 day lead times, giving you a dependable, smooth, laser-friendly material for creative and functional projects.