Neoprene Rubber is a versatile, weather-resistant material that maintains reliable performance across a wide range of temperatures. It’s a solid choice for custom gaskets, seals, and general-purpose parts that need balanced durability, flexibility, and moderate oil resistance.

Instant quote

A: 1″ x 1″

B: 30″ x 44″

Custom quote

C: 30″ x 44″

.063″ (1.60mm)

.125″ (3.18mm)

Neoprene Rubber, also known as chloroprene (CR), is a durable synthetic rubber formulated with fillers and curatives to deliver a well-balanced mix of mechanical and environmental performance. It offers strong resistance to weathering, ozone, and UV exposure while maintaining stable behavior across common gasket and sealing temperature ranges. With moderate oil and chemical resistance and dependable flexibility, neoprene is a go-to material for custom gaskets, seals, bumpers, pads, and general-purpose components. Its combination of durability and versatility makes it a practical solution for both industrial applications and everyday fabrication projects.

Neoprene is chosen for versatile gasket, sealing, and cushioning applications where durability, weather resistance, and flexibility are essential. Here are a few common uses cases for this material.

We source this high-demand metal through trustworthy suppliers with verifiable industry credentials so you don’t have to worry about it. You’ll know that our 5052 aluminum sheets are ready to be transformed into your greatest ideas.

Material certifications (PDF) are available below.

5052 Aluminum .040″

5052 Aluminun .063″

5052 Aluminum .080″

5052 Aluminum .100″

5052 Aluminum .125″

5052 Aluminum .190″

5052 Aluminum .250″

5052 Aluminum .375″

5052 Aluminum .500″

We guarantee awesome quality parts. If you’re not 100% happy, we’ll give you a refund or remake on the spot – no questions, no hassle.

Neoprene rubber comes in .063″ (1.6mm) and .125″ (3.2mm) thicknesses.

The minimum cut size for neoprene rubber is 1″ x 1″ and the maximum cut size us 30″ x 44″.

No available services are available for neoprene rubber.

We accept .ai, .dxf, .dwg, .eps, .stp, and .step

Customize one of our simple parts templates

Neoprene rubber is a widely used synthetic elastomer known for its durability, weather resistance, and versatility in both indoor and outdoor applications. It is one of the most dependable general purpose rubber materials for gaskets, pads, insulation components, vibration damping, and protective parts. Neoprene offers a balanced mix of flexibility, strength, and environmental resistance, which makes it a popular choice across industrial, automotive, marine, and consumer product sectors.

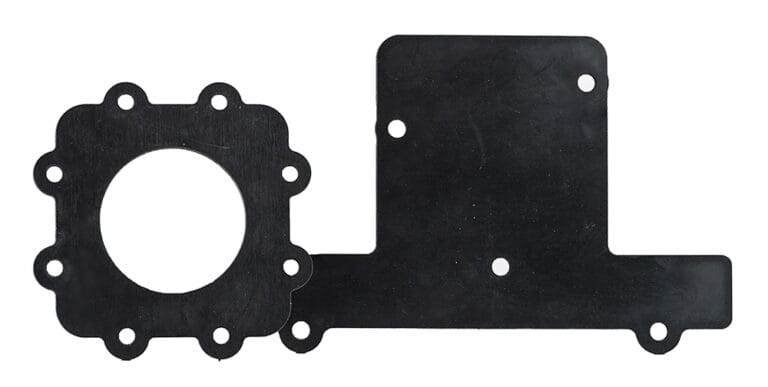

At SendCutSend, we waterjet cut .063 inch and .125 inch neoprene rubber to ±.009 inch tolerance, producing accurate gasket shapes, seals, pads, and custom rubber components ready for installation.

• Strong general purpose rubber suitable for many applications • Good resistance to weather, ozone, and UV exposure • Handles oils, greases, and mild chemicals • Cuts cleanly with waterjet for accurate gasket geometry • Flexible, durable, and long lasting under compression and mechanical stress

Neoprene is chosen because it performs reliably in situations where a gasket or rubber part must withstand environmental exposure, mechanical pressure, vibration, and moderate contact with oils or chemicals. It offers a good balance of sealing ability, durability, and flexibility, making it suitable for a variety of applications.

Fabricators often choose neoprene because: • It performs well outdoors • It handles ozone and sunlight better than many rubbers • It offers good compression recovery when clamped • It resists tearing and abrasion • It works well for vibration isolation • It is compatible with many fluids and oils

Neoprene is commonly used when an application requires durability but does not need the high oil resistance of Buna N, the extra structural integrity of fabric-reinforced neoprene, or the high elasticity of silicone.

Neoprene is known for its strong weather resistance. Many rubbers degrade in sunlight and outdoor conditions, but Neoprene performs well outdoors because it: • Resists UV exposure • Handles ozone and oxidation • Maintains flexibility in a wide range of temperatures • Does not crack easily from weathering • Resists moisture and water exposure

This makes neoprene suitable for outdoor gaskets, marine components, HVAC systems, and weather seals where long-term exposure is unavoidable.

Neoprene handles compression well and forms a reliable seal when clamped between two surfaces. It is not as soft or stretchy as silicone, but this firmness helps it maintain shape and sealing force.

Neoprene performs well when the gasket must: • Seal out air or water • Maintain pressure under bolt load • Withstand moderate chemical exposure • Absorb vibration or shock • Stay flexible in cold or hot environments

It is commonly used in HVAC systems, compressors, pumps, marine equipment, and general sealing surfaces in machinery.

Neoprene remains flexible and durable even after prolonged exposure to sunlight, ozone, and temperature changes.

Neoprene handles: • Oils • Mild solvents • Greases • Water • Coolants

It is not as oil resistant as Buna N but still performs well with many common liquids.

Neoprene withstands abrasion, compression cycles, repeated bending, and mechanical impacts without degrading quickly.

The material compresses and rebounds predictably, which makes it excellent for gaskets that need to maintain a seal over time.

Neoprene absorbs energy and dampens vibration, which is useful for pads, bumpers, isolators, and protective components.

Although neoprene is moderately oil resistant, Buna N is better suited for continuous contact with oils, fuels, or petroleum products.

Neoprene is not suitable for extreme heat or freezing environments where silicone or specialty elastomers may be required.

Neoprene is durable and flexible but does not stretch to the same degree as high elasticity rubbers.

Waterjet cutting avoids burning, but some materials may show faint texture or minor marks where the jet transitions.

Rubber compresses and flexes, so neoprene is not suitable for parts requiring extremely tight tolerances.

Neoprene is a very waterjet friendly material. It cuts cleanly without burning, melting, or producing fumes.

What to expect from waterjet cut neoprene: • Clean, uniform edges • No heat affected zones • Accurate bolt holes and internal cutouts • Smooth curves and tight geometry • No fraying or tearing

Waterjet cutting is the best method for neoprene, since laser cutting would burn rubber and create fumes.

Neoprene is flexible and forgiving, but thoughtful design ensures long lasting parts.

• Use minimum feature sizes of at least .060 inch for .063 inch material • For .125 inch neoprene, keep narrow walls above .090 inch • Avoid extremely sharp internal corners and incorporate fillets • Ensure bolt holes are large enough to prevent pinching or tearing • Plan for moderate compression during sealing • Avoid very tight press fits since rubber will deform • Use smooth transitions in gasket paths instead of jagged geometry

For general design considerations, visit SendCutSend Design Guidelines

Neoprene is used in many industries because of its durability and outdoor performance. Common applications for neoprene rubber include:

• HVAC gaskets and seals • Marine and boating components • Weather stripping • Vibration dampening pads • Shock absorbing bumpers • Automotive parts and gaskets • Electrical enclosure seals • Protective padding and isolators • General purpose mechanical seals

Its balance of weather resistance, flexibility, and durability makes it a go-to material for both industrial and consumer applications.

Choose neoprene rubber when you need a durable, weather resistant, moderately oil tolerant gasket material that performs reliably outdoors or in general mechanical environments.

Use neoprene if your project requires: • A dependable seal under compression • Good performance with water, chemicals, or moderate oils • Vibration isolation or cushioning • Components that will be exposed to sunlight or weather • Flexible but tough material for pads or gaskets

Neoprene is not the best option for: • Continuous oil or fuel exposure • High temperature systems • Applications requiring high stretch or softness

SendCutSend waterjet cuts .063 inch and .125 inch neoprene rubber with ±.009 inch accuracy and ships in 2 to 4 days, providing dependable parts for mechanical, industrial, and outdoor use.