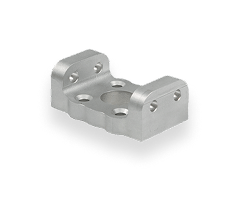

Multiaxis CNC machining in billet stock.

Bends within 1 degree of accuracy or better.

Allow hardware to sit flush on your parts to reduce wear and tear.

Reinforce and enhance your parts with dimples up to 3”

Add strong, permanent fasteners to your metal parts.

Easily add threading to allow for the addition of hardware to your parts.

Increase durability with Class II anodizing services available in 5 colors.

Smooth sharp edges and clean up your metal parts.

Increase rust prevention, wear resistance, and strength with zinc and nickel plating.

Give your custom cut parts a bold, long-lasting protective layer in one of 11 options.

Reduce the surface blemishes and handling scratches found in raw materials.

Have your own file? Upload it now to see instant pricing!

Size: 3.6 x 2.5″

Laser Cutting, Deburring

Size: 1.4 x 5.2″

Laser Cutting, Deburring

Size: 2.6 x 2.9″

CNC Routing, Tapping

Size: 9 x 6.6″

Laser Cutting, Anodizing, Bending, Deburring, Hardware

Size: 6.7 x 4.25″

Waterjet Cutting

3 thicknesses: .125" - .234"

2 thicknesses: .118" & .236"

3 thicknesses: .118" - .214"

1 thickness: .025"

10 thicknesses: .040" - .500"

11 thicknesses: .040" - .750"

CNC Machining

3 thicknesses: .125" - .250"

1 thickness: .250"

5 thicknesses: .119" - .500"

2 thicknesses: .354" - .472"

1 thickness: .015"

5 thicknesses: .040" - .250"

6 thicknesses: .040" - .197"

1 thickness: .030"

5 thicknesses: .050" - .250"

5 thicknesses: .040" - .250"

2 thicknesses: .063" - .125"

2 thicknesses: .125" - .270"

4 thicknesses: .063" - .375"

5 thicknesses: .030" - .074"

1 thickness: .125"

3 thicknesses: .250" - .500"

2 thicknesses: .125" & .187"

3 thicknesses: .125" - .375"

4 thicknesses: .125" - .500"

12 thicknesses: .030" - .500"

3 thicknesses: .118" - .220"

3 thicknesses: .875" - 2.250"

10 thicknesses: .030" - .500"

4 thicknesses: .060" - .250"

1 thickness: .040"

5 thicknesses: .040" - .250"

2 thicknesses: .375" - .500"

Get started on your project with the click of a button. Whether you have a CAD file, a sketch, or just an idea.

We take pride in our customer service, quality, and continual innovation with new products and services. You’re in good hands with SendCutSend.

Please note: Pricing examples on our website are provided as general estimates and may not always reflect current prices. While we strive to keep these examples accurate, uploading your file is the best way to see instant current pricing.

Jim and Jake, our founders, experienced frustration with the time and money consumed in acquiring custom parts for their projects. Armed with expertise in software development, they launched SendCutSend as their solution.

We accept

DXF, EPS, DWG, and AI files.

Choose from over 60 customizable laser cutting templates.

We’ll review your file and convert to configurable part in your SendCutSend account.

We can scan and convert your paper, foam or cardboard templates.

Ready to order but don’t have your file handy? Enter your email below and we’ll send you a link for our desktop uploader.