The low melting point of ABS lends itself to injection molding and 3D printing, and ABS is also a great candidate for CNC routing. Our custom cut ABS plastic parts are heat resistant, durable, and BPA free, making it a multi-purpose material with dozens of applications ranging from the food industry to aerospace engineering.

Instant quote

A: 1″ x 2″

B: 30″ x 44″

Custom quote

C: 30″ x 47″

.125″ (3.18mm)

.187″ (4.75mm)

.234″ (5.94mm)

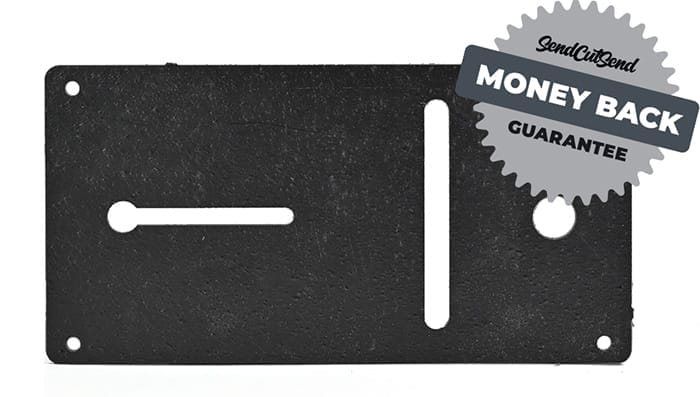

Please note (especially for mirroring parts), the finishes on the front and back of ABS plastic differ. The top side is textured and the back will be glossy. We will cut your file texture side up.

The orientation of your part as shown in the part preview will be considered the top side.

These tabs hold your parts in place while being cut to ensure the best accuracy possible. Click below to learn what to expect and how to best design with these tabs in mind.

ABS plastic is a sturdy thermoplastic that is often used in prototyping due to its low cost and high strength-to-density ratio. With a tensile strength of 4,100 psi, ABS parts are well-suited for high stress applications that require a low weight material.

Outside of prototyping, ABS plastic parts are most commonly used in dashboards, seat backs, and instrument paneling in the automotive and construction industries.

As with most plastics, you need to protect your custom ABS parts from high-heat situations due to its low continuous operation temperature (about 150 degrees F). In the right application, however, this lightweight and low-cost plastic can bring a new kind of strength to your project.

Be sure to read up on our design guidelines for CNC routing materials as the tooling requirements are different from laser cutting.

We guarantee awesome quality parts. If you’re not 100% happy, we’ll give you a refund or remake on the spot – no questions, no hassle.

SendCutSend offers ABS Plastic in three thickness options: .125″ (3.18mm), .187″ (4.75mm), and .234″ (5.94mm).

When ordering ABS Plastic through SendCutSend, there are specific size and thickness parameters to keep in mind. For instant quoting, the smallest part size available is 1″ x 2″, while the largest part supported is 30″ x 44″. For larger projects, custom quotes are available for sizes up to 30″ x 47″.

You can add the following services to your ABS parts:

Countersinking and Tapping

We accept .ai, .dxf, .dwg, .eps, .stp, and .step

Customize one of our simple parts templates

ABS (Acrylonitrile Butadiene Styrene) is one of the most widely used engineering plastics thanks to its toughness, impact resistance, and excellent machinability. It’s strong enough for functional mechanical parts yet forgiving enough for fast prototyping and iterative design. Fabricators, engineers, and makers choose ABS when they need a material that cuts cleanly, withstands impact, and holds threaded fasteners — without cracking or chipping. At SendCutSend, we CNC route USA-sourced ABS plastic in .125”, .187”, and .234” thicknesses to ±.005” tolerance, making it ideal for custom enclosures, shop fixtures, panels, and small engineering components.

These traits make ABS one of the most practical plastics for real-world mechanical parts and functional prototypes.

Fabricators choose ABS because it strikes a rare balance between rigidity, durability, and machinability. Unlike acrylic, it won’t crack under stress. Unlike HDPE, it holds its shape and resists flexing. Unlike Delrin, it remains affordable and easy to route in large panels. Common reasons people choose ABS:

ABS is function-first plastic. It’s ideal for parts that will actually be used, handled, or exposed to stress.

ABS routes extremely well. The material remains stable under tool pressure and evacuates chips cleanly, resulting in sharp edges and accurate geometry. Key routing behaviors:

SendCutSend routes ABS to ±.005” tolerance, ensuring precise fitment for mechanical parts and enclosures.

ABS is forgiving, but good design choices ensure reliable, long-lasting parts.

More guidance is available in the SendCutSend design guidelines.

Popular applications include:

ABS is widely used in industry because it’s dependable, easy to machine, and strong enough for everyday functional components.

SendCutSend sources ABS plastic from domestic U.S. suppliers, ensuring stable supply, consistent quality, and reliable performance. All fabrication, inspection, and shipping of ABS plastic parts through SendCutSend take place in our three U.S. manufacturing facilities:

This U.S-based workflow allows us to maintain tight tolerances, fast lead times, and dependable material availability for every order.

Choose ABS plastic when you need a tough, machinable, lightweight engineering plastic that’s strong enough for real mechanical use. It’s ideal for enclosures, fixtures, tooling, panels, and functional prototypes that need durability without brittleness. You should consider ABS when your part requires:

At SendCutSend, we CNC route USA-sourced ABS plastic to ±.005” precision with 2–4 day lead times, giving makers, engineers, and manufacturers fast access to one of the most versatile plastics in fabrication.