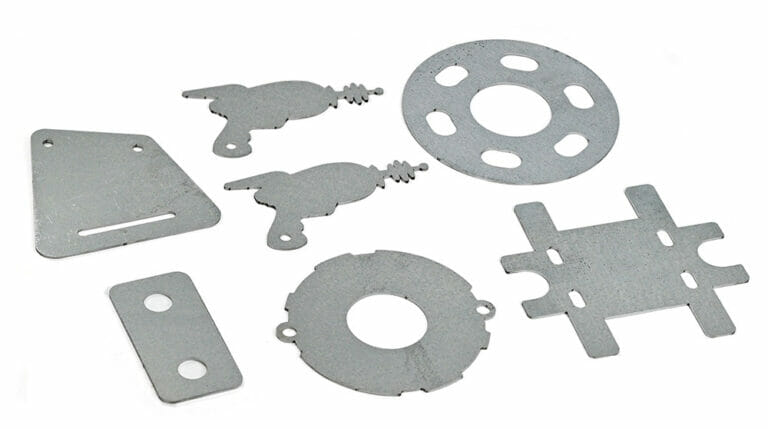

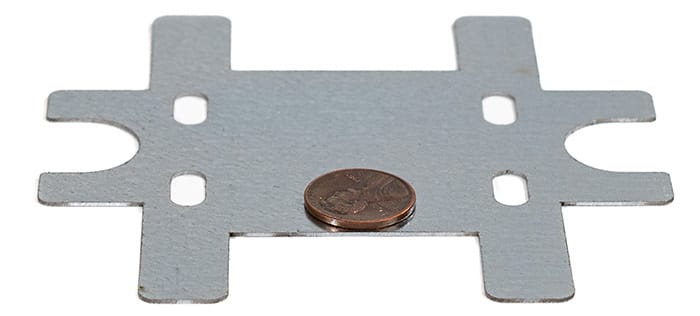

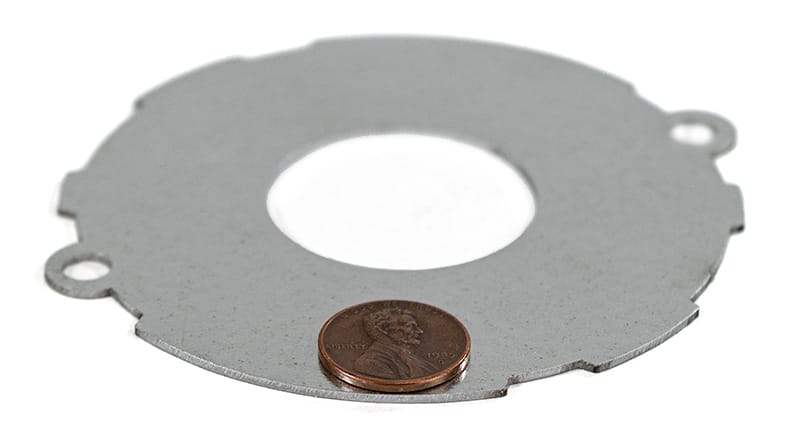

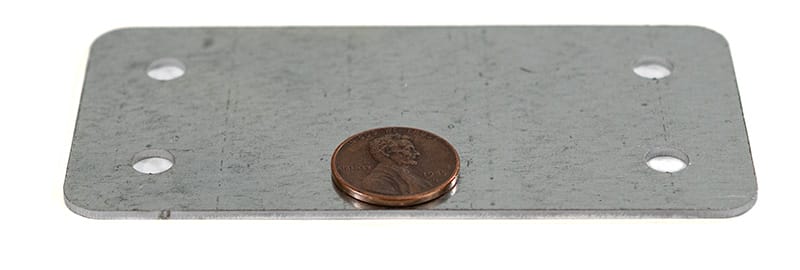

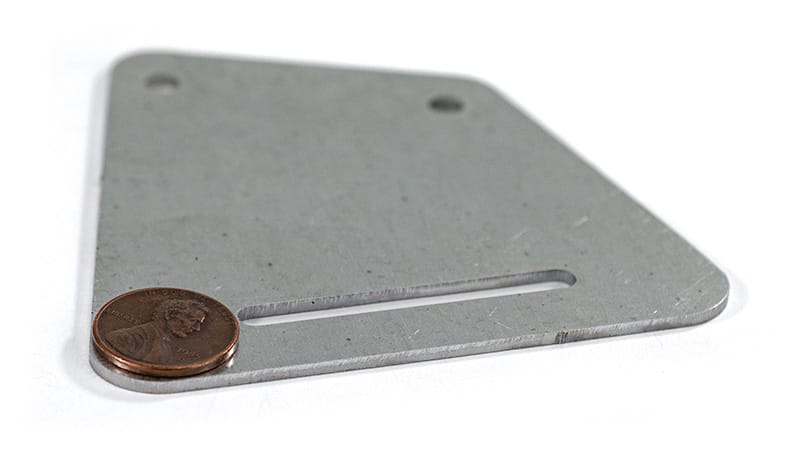

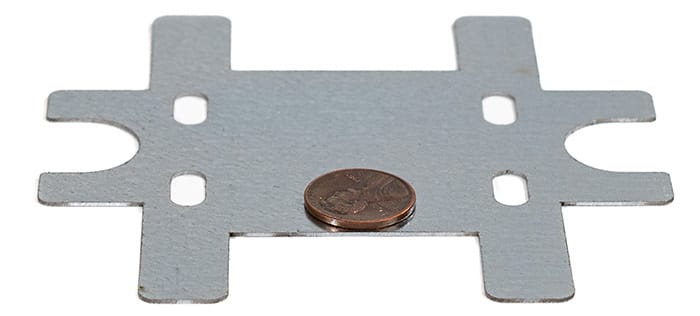

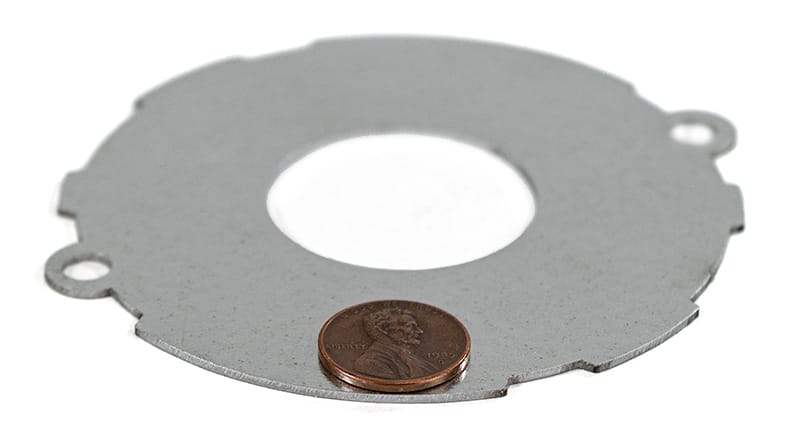

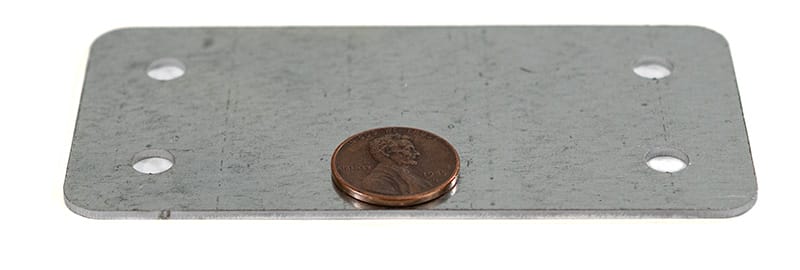

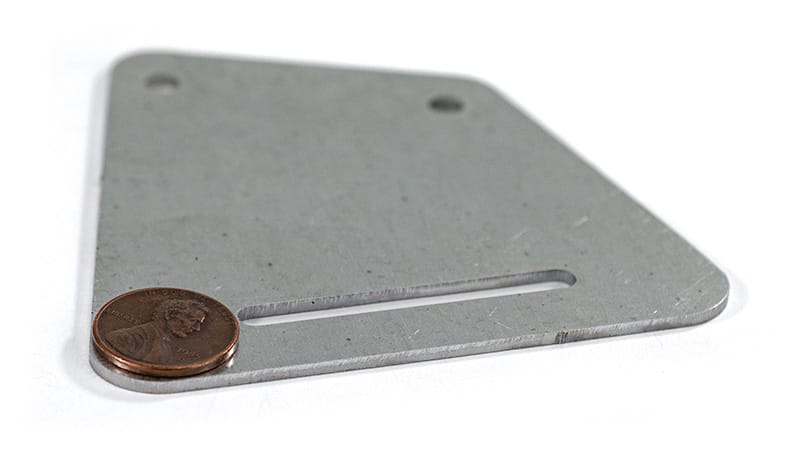

Laser cut, +/- .005" tolerance

G90 steel, a hot-dip galvanized steel with a coating weight of 90 grams per square meter, offers a myriad of benefits in various industrial applications. Ideal for outdoor applications like construction and automotive components, it combines durability with visual appeal. Its formability and weldability streamline manufacturing processes, while the zinc coating enhances overall strength. The longevity of G90 steel not only ensures durability but also contributes to sustainability by reducing the need for frequent replacements, making it a preferred material for diverse industrial uses.

G90 steel is a go-to choice for various applications spanning different industries. Since it doesn’t rust easily, it’s an ideal material for outdoor and marine environments.

We guarantee awesome quality parts. If you’re not 100% happy, we’ll give you a refund or remake on the spot – no questions, no hassle.

This material is available in five thickness options: .030″ (0.76mm), .036″ (.91mm), .048″ (1.22mm), .059″ (1.50mm) and .074″ (1.88mm).

SendCutSend cuts G90 Galvanized Steel in a broad range of sizes and thicknesses. Instant quoting is available for parts as small as .25″ x .375″ and as large as 30″ x 44″. Larger parts, up to 30″ x 56″, can be ordered through a custom quote.

You can add the following services to your G90 Galvanized Steel parts:

Bending, Dimple Forming, Hardware Insertion, and Tapping

We accept .ai, .dxf, .dwg, .eps, .stp, and .step

Customize one of our simple parts templates

G90 galvanized steel is a go-to material when corrosion resistance and clean appearance need to work hand in hand. Coated with a layer of zinc for protection, it’s tough, formable, and ideal for enclosures, brackets, and structural parts that need to last. Below, we cover the most common questions about G90 steel and how to get reliable results when designing for SendCutSend’s laser cutting and forming services.

G90 steel is cold-rolled mild steel coated in zinc through the hot-dip galvanizing process. The zinc layer provides both barrier protection (sealing the steel from moisture) and cathodic protection (sacrificing itself to prevent rust if the coating is scratched). The “G90” rating indicates 0.90 ounces of zinc per square foot, offering one of the most durable galvanic coatings available for sheet applications.

G90 steel combines the base strength of mild steel with the surface protection of zinc. Typical properties:

This makes it a smart pick for outdoor brackets, housings, and panels where raw steel would rust over time.

The difference is in the zinc coating thickness.

If your part will face outdoor exposure, condensation, or humidity, G90 is the better choice. At this time, SendCutSend stocks G90 sheet metal but does not stock G60.

G90’s strength and corrosion resistance make it a favorite for industrial and architectural uses. You’ll see it in:

Explore more options for your next project in our Material Catalog.

SendCutSend laser cuts G90 with ±.005″ precision, achieving clean edges without damaging the zinc coating.

For detailed feature and hole sizing, check our Design Guidelines.

Laser cut G90 parts hold ±.005″ tolerances and ship with a clean, matte metallic finish.

For dimensional and feature info, see the G90 steel specifications.

Yes, G90 bends well with minimal risk of cracking or coating flake-off.

SendCutSend offers bending on G90 Galvanized Steel. For precision bends, review our Bending Guidelines.

Yes, SendCutSend offers tapping, dimple forming, and PEM hardware insertion of G90 Galvanized Steel. This material takes threads and hardware inserts very well.

Before adding additional services to your custom cut G90 parts, read our service guidelines.

Welding G90 is possible but requires care. The zinc layer produces fumes when heated, so always weld with proper ventilation and respirator protection. After welding, grind or brush off the weld area and apply a cold galvanizing spray or zinc-rich primer to restore corrosion resistance. For most SendCutSend parts, we recommend fasteners or inserts as cleaner joining methods.

The zinc coating provides long-term corrosion protection that can last decades depending on environment.

Periodic cleaning or touch-up extends its service life significantly.

Keep coating integrity and bend radius in mind when designing for galvanized steel.

For all design considerations, check our full Design Guidelines.

G90 galvanized steel gives you the durability of steel with the rust protection of zinc — strong, affordable, and ready for long-term use. With SendCutSend’s laser cutting accuracy (±.005″) and available bending, dimple forming, hardware insertion, and tapping services, your G90 parts arrive ready to assemble and built to last. Compare G90 with other sheet steels and finishes in our Material Catalog.