Can't find what you're looking for?

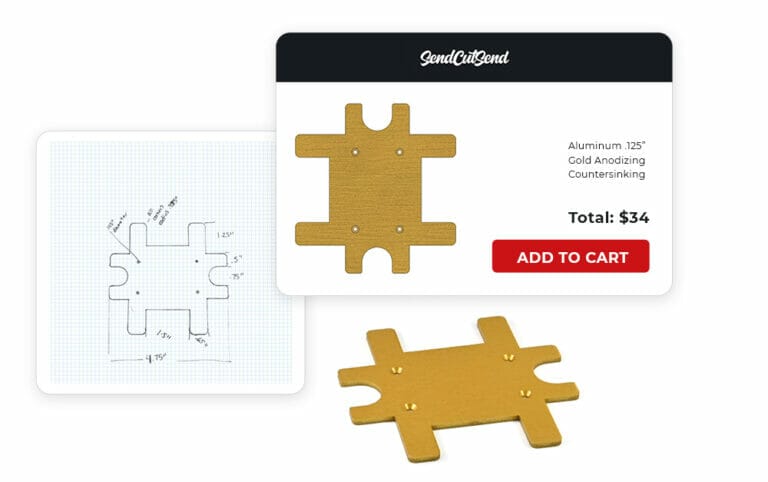

Get started on your project with the click of a button. Whether you have a CAD file, a sketch, or just an idea.

3 thicknesses: .125" - .234"

2 thicknesses: .118" & .236"

3 thicknesses: .118" - .214"

1 thickness: .025"

10 thicknesses: .040" - .500"

9 thicknesses: .040" - .500"

3 thicknesses: .125" - .250"

1 thickness: .250"

5 thicknesses: .119" - .500"

2 thicknesses: .354" - .472"

1 thickness: .015"

5 thicknesses: .040" - .250"

6 thicknesses: .040" - .197"

1 thicknesses: .030"

5 thicknesses: .050" - .250"

5 thicknesses: .040" - .250"

2 thicknesses: .063" - .125"

2 thicknesses: .125" - .270"

4 thicknesses: .063" - .375"

5 thicknesses: .030" - .074"

1 thickness: .125"

3 thicknesses: .250" - .500"

3 thicknesses: .125" - .375"

4 thicknesses: .125" - .500"

12 thicknesses: .030" - .500"

3 thicknesses: .118" - .220"

10 thicknesses: .030" - .500"

4 thicknesses: .060" - .250"

1 thickness: .040"

5 thicknesses: .040" - .250"

2 thicknesses: .375" - .500"