Filter by

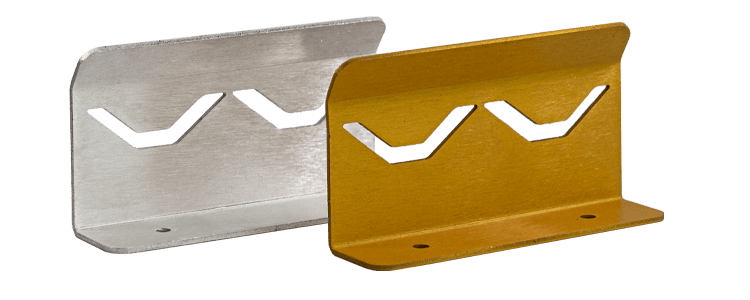

1 color | CNC Routed

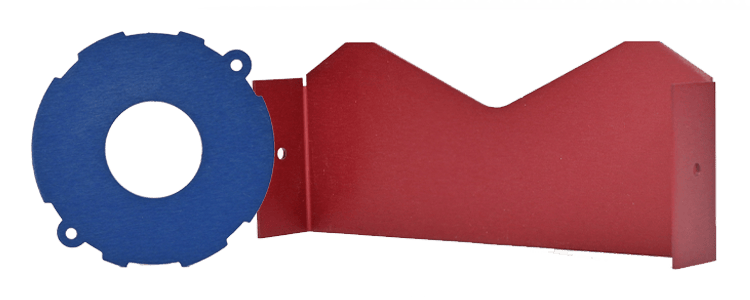

3 colors | CNC Routed

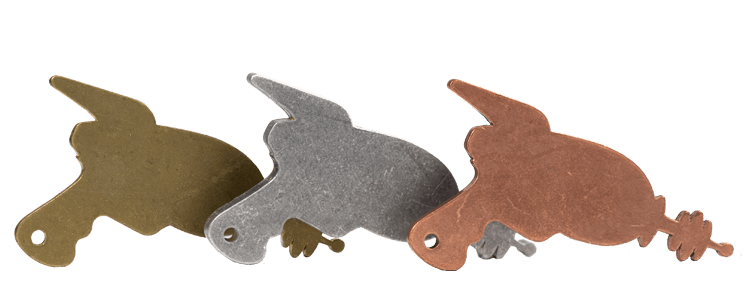

10 colors | Laser Cut

1 finish | Laser Cut

1 finish | Laser Cut

1 finish | Laser Cut

1 finish | Laser Cut

1 finish | Laser Cut

1 finish | Laser Cut

1 finish | CNC Routed

1 finish (1075) | Laser Cut

1 finish | Laser Cut

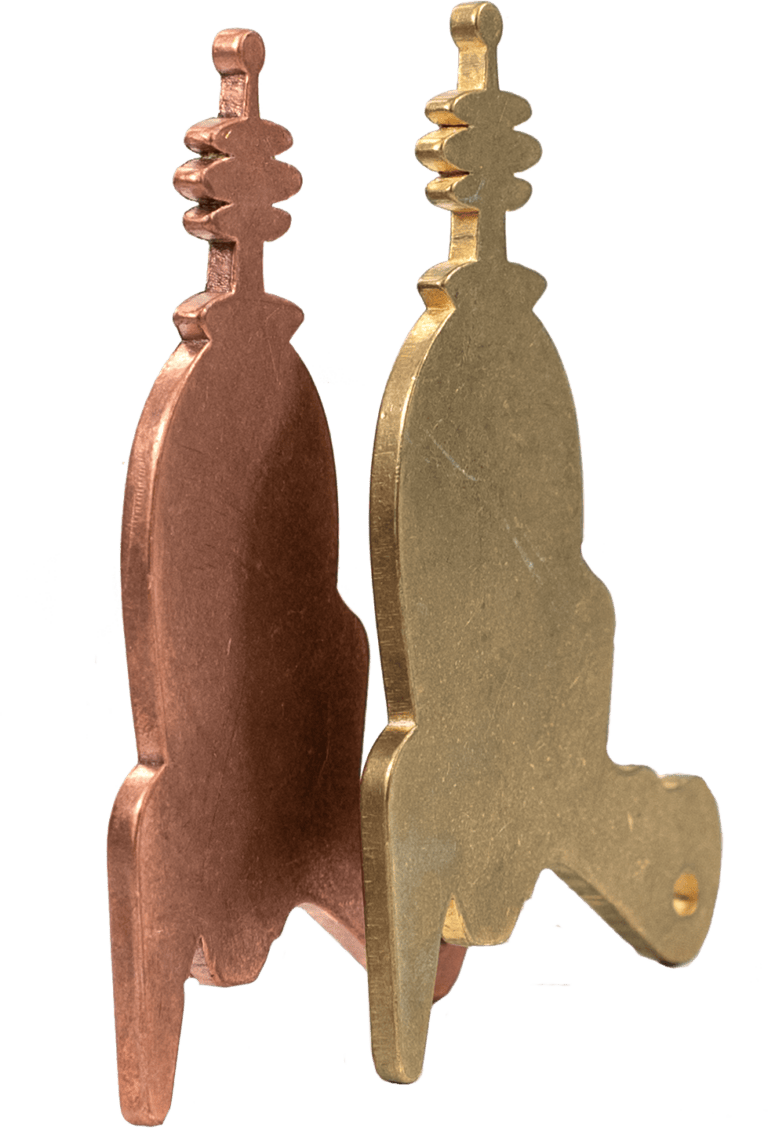

1 finish | Waterjet

1 finish | Laser Cut

1 finish | Laser Cut

1 finish | Laser Cut

1 finish | Laser Cut

1 finish | Laser Cut/CNC Routed

1 finish | Waterjet

1 finish | Laser Cut

1 finish | Laser Cut

2 colors | CNC Routed

1 finish | Laser Cut

1 finish | Waterjet

1 finish | Laser Cut/CNC Routed

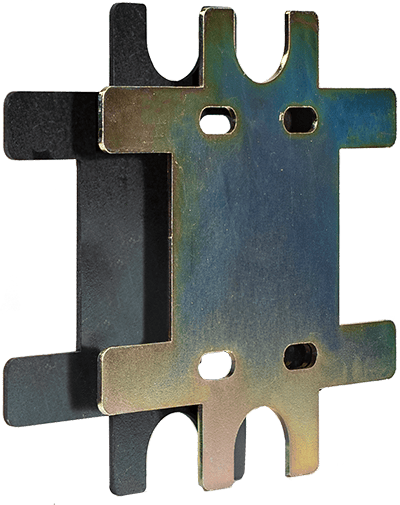

A36/1008/1018 | Laser Cut

1 finish | CNC Routed

1 finish | Laser Cut

1 finish | Laser Cut

1 finish | Laser Cut

1 finish | Laser Cut

2 colors | CNC Routed

Get started on your project with the click of a button. Whether you have a CAD file, a sketch, or just an idea.

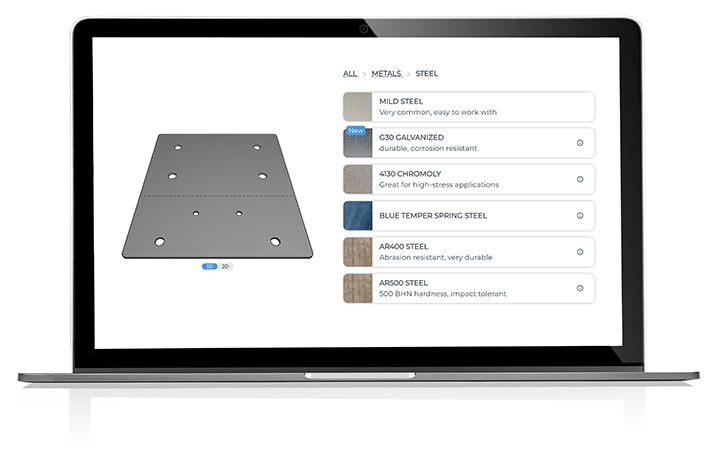

Not sure which material is right for your project? Check out our Material Selection Guide.

Covers all materials and thicknesses

Covers sizing specifications for all our post-processing services.

Everything you need to know before you design your first part.

Tips for reducing design density, which saves you money!

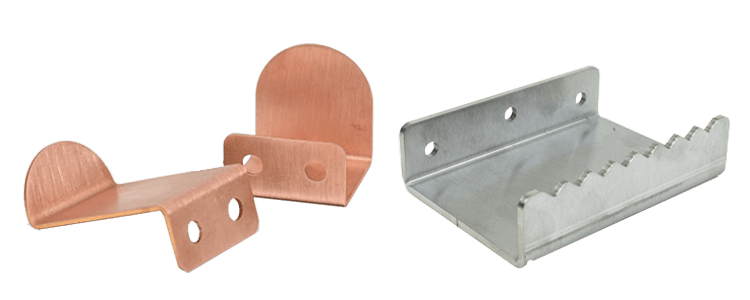

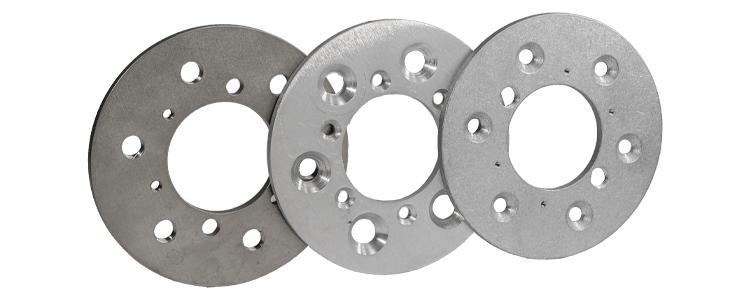

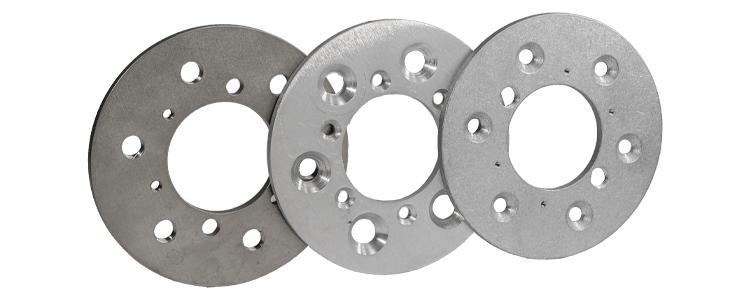

Custom laser cutting, waterjet cutting, and CNC routing. We’ll cut your parts with the method best suited for your sheet or plate material.

2-4 days standard production

Our fast laser tube cutting services deliver precisely manufactured parts in round, square, and rectangular tube metal materials.

2-4 days standard production

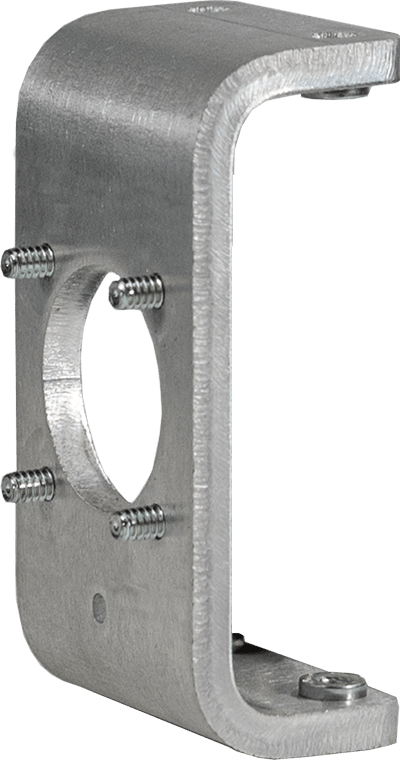

Multiaxis CNC machining in billet stock. This subtractive process uses precise machining to sculpt blocks of raw metal into nearly anything you can imagine.

2-4 days standard production

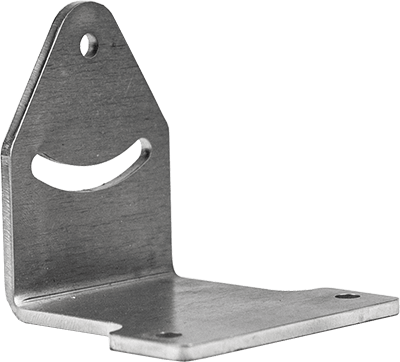

Add dimension to your projects with our precision CNC bending services.

+1-2 days | 10 materials

Allow hardware to sit flush on your parts to reduce wear and tear.

+1-3 days | 6 materials

Strengthen material with aesthetically pleasing dimples.

+1-3 days | 7 materials

Easily add text and small details to your custom cut parts with our metal laser engraving services.

+1-3 days | 3 materials

Select from our catalog of PEM press-fit hardware to add nuts, studs, and standoffs.

+1-3 days | 8 materials

Quickly and easily add threading to allow for the addition of hardware to your parts.

+1-3 days | 12 materials

We offer Class II anodizing services to add durability and character to your laser cut parts.

+7-10 days | 3 materials

This process removes small imperfections, scratches, and burr left over from the cutting process.

+0 days | 8 materials

Increase rust prevention, wear resistance, and strength with zinc and nickel plating.

+7-10 days | 3 materials

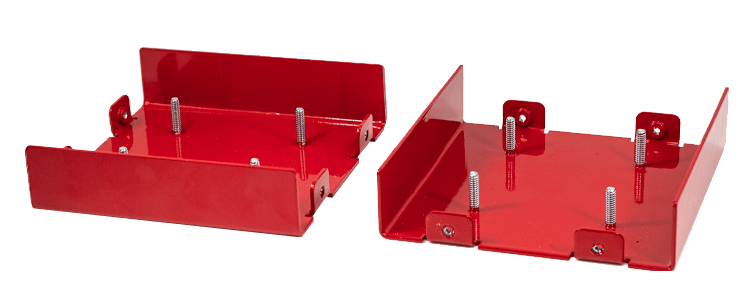

Give your laser cut parts a bold, long-lasting finish and protective layer in one of 7 colors, 4 finishes

+7-10 days | 9 materials

Reduce the surface blemishes and handling scratches found in raw materials.

+1-2 days | 11 materials