With nearly double the tensile strength and almost double the shear strength of 6061, our 7075 aluminum is laser cut and is one of the best options available when high-strength and low-weight are important.

Instant quote

A: .25″ x .375″

B: 30″ x 44″

Custom quote

C: 30″ x 47″

.125″ (3.18mm)

.190″ (4.83mm)

.250″ (6.35mm)

7075 Aluminum is our toughest and strongest aluminum alloy. Like 6061 aluminum, 7075 aluminum was made for use in the aerospace industry, where it’s used extensively. It’s lightweight and durable, so it also lends itself to bike frames, rock climbing equipment, and other high stress environments.

7075 sacrifices some of 5052 aluminum’s workability, formability, and weldability for increased hardness, strength, and overall toughness.

Still carrying the benefits of other aluminum alloys, such as lower weight and high fatigue strength, 7075 aluminum positions itself dominantly as having one of the best strength to weight ratios in any aluminum alloy.

We guarantee awesome quality parts. If you’re not 100% happy, we’ll give you a refund or remake on the spot – no questions, no hassle.

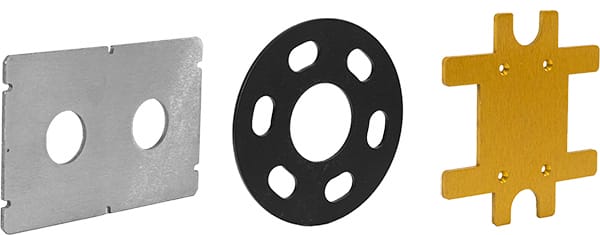

SendCutSend offers 7075 T6 Aluminum in three thickness options: .125″ (3.18mm), .190″ (4.83mm), and .250″ (6.35mm).

With SendCutSend’s 7075 T6 Aluminum offering, you can get parts instantly quoted if they fall between .25″ x .375″ and 30″ x 44″. Custom quotes are available for sizes up to 30″ x 56″.

You can add the following services to your 7075 T6 Aluminum parts:

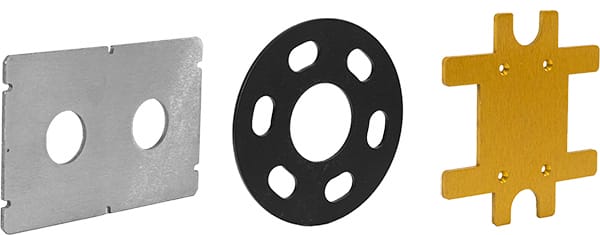

Anodizing, Countersinking, Deburring, Hardware Insertion, Powder Coating, Tapping, and Tumbling

We accept .ai, .dxf, .dwg, .eps, .stp, and .step

Customize one of our simple parts templates

7075 aluminum is the strongest aluminum alloy offered by SendCutSend, known for its exceptional strength-to-weight ratio and use in aerospace, motorsports, and high-performance engineering applications. It’s part of the 7xxx series, which uses zinc as its primary alloying element to achieve tensile strengths that rival low-carbon steels — all while remaining significantly lighter. While 7075-T6 provides outstanding performance under load, it comes with trade-offs: limited corrosion resistance, low weldability, and more challenging formability. This guide covers everything you need to know before designing, cutting, and finishing parts in 7075 aluminum.

The T6 temper represents the peak-strength condition for 7075 aluminum — achieved through solution heat treatment and artificial aging. It’s one of the few aluminum grades strong enough to replace steel in many structural applications while maintaining excellent fatigue strength.

7075-T6 is one of the highest strength-to-weight aluminum alloys available. It maintains excellent fatigue resistance and rigidity, but requires more careful handling during fabrication and finishing.

SendCutSend laser cuts 7075 aluminum to a ±.005” tolerance. The alloy’s hardness provides clean, sharp edges with minimal burrs. However, heat buildup must be controlled to prevent localized softening.

Design guidelines are similar to other aluminum alloys but with more conservative spacing:

Keep thermal exposure low. Prolonged heat during post-processing (grinding, sanding, etc.) can reduce the T6 hardness.

7075 takes surface finishes well. Anodizing and powder coating both improve corrosion resistance and extend lifespan in harsh environments. For structural applications requiring maximum strength and minimal oxidation, clear anodizing is common.

Because of its exceptional strength and rigidity, 7075-T6 aluminum is used in advanced engineering and performance-driven industries:

If your part requires maximum stiffness and minimal weight — and corrosion protection or welding aren’t concerns — 7075 is likely the top-performing alloy for the job.

7075-T6 aluminum represents the pinnacle of strength in the aluminum family. It combines near-steel tensile strength with exceptional fatigue resistance and a low weight that makes it indispensable in performance-critical designs. While it doesn’t offer the weldability or corrosion resistance of 6061 aluminum or 5052 aluminum, its unmatched mechanical performance makes it the go-to choice for high-load, high-precision, and aerospace-grade applications. At SendCutSend, we laser cut 7075-T6 aluminum sheets with ±.005” tolerance and 2–4 day turnaround, offering the same precision and consistency as our other aluminum materials. When your design demands maximum strength and minimum weight, 7075 aluminum delivers the performance edge.